How to Fix Common Bobcat 331 Mini Excavator Problems?

The Bobcat 331 is very lightweight compared to its closest competitors, which makes it highly portable. For that reason, this mini excavator is the choice of many people. However, according to our analysis, most customers face some general issues with the same machine.

So, what are the common Bobcat 331 problems? We found many, but the most common issues are hydraulic leaks on the swing motor, weak stick and swing, and case drain failure. There are other issues, but these seem to be the most common ones.

We will provide some solutions to the common bobcat 331 problems throughout the article, and we hope you will find your solution here too. Read more to learn.

What Are The Common Bobcat 331 Problems?

There are plenty of problems with Bobcat 331 because of its lightweight. It was designed to be lightweight and portable, giving people many benefits. But to have something, you have to lose something. So, as a result, consumers face many problems while using this mini excavator.

There are issues that you can solve by yourself, and for some, you might need an expert. Let’s look at some common Bobcat 331 problems:

● Final drive rotator problem

● Case Drain failure

● Weak stick and swing

● Hydraulic Leak

● Bucket Stalls while working

● Shut-off Fuel Solenoid fails

6 Easy Solutions For Bobcat 331 Problems

Calling a mechanic or going to the dealership can be very expensive to fix bobcat 331 as they will tell you to get a new part, and the parts are costly. So before going to anyone else, you should try to fix the problems yourself and save some extra dollars.

Try the solutions given below in your garage. We hope you will find the perfect solution to your problems.

1. Repair the Final Drive Rotator

This is one of the most critical components of any mini excavator, especially on bobcat 331. The machine won’t function properly if the final drive rotator is damaged.

You will notice visible damage on the front section and smelly gear oil. The manufacturer suggests changing the oil after 250 operating hours. Here are the steps you can follow to fix this problem:

- Step 01: Open the front section and look for any damage. Open the face seal and bring out the rotator group.

- Step 02: Look for main seal damage. Repair any existing damage.

- Step 03: Unbolt the rotator and observe if any parts are damaged. If any components are damaged, buy and replace that specific part.

- Step 04: The valve block ring might also be damaged, so replace it.

If there is severe damage to the rotator, bring it to a professional. Otherwise, you can buy separate parts, which start from $380 up to $1,200 depending on the parts you need.

Note: Avoid high pressure on the hydraulics. Replace the bearing if necessary.

2. Replace Case Drain Filter and Clean the lines

A case drain filter can be an issue as it filters different components in the hydraulics. It should be cleaned or replaced after a specific time, and you should keep an eye on it before it gets too blocked to be repaired.

When the filters get blocked, the hydraulic pressure drops as it faces obstacles while operating. Replacing the case drain filter can solve this problem. Here’s how you can replace it by yourself without any professional help:

- Step 01: Open the back cache and find the case drain filter. It should be near the hydraulic pumps and lines.

- Step 02: Unplug the filter and open it. We do not suggest cleaning it. You should buy a new one and replace it in the same position.

- Step 03: Follow the lines where the fluid travels and check if the pipe is clogged. Cleaning it after 100 hours of work is recommended.

- Step 04: If you see any damage or leak on the pipe, then buy a new one and replace it. Unbolt the connector and reconnect after replacing the line.

The filter costs around $20.49, and the fluid pipe will cost about $50. Although, it depends on the brand and quality.

3. Adjusting the Pressure for Weak Stick and Swing

Hydraulic Pump pressure can cause the stick and swing to be weak because they both operate via that source. You will need a pressure-checking kit to understand how the pressure is distributed. Then check both of your controller sticks.

They should feel uneven, and as a result, the swing will also be weak. Follow the steps below to adjust the pressure:

- Step 01: Open the back of the excavator. Follow the line from the hydraulic pump that should lead you to under the seat or the left stick.

- Step 02: There are a lot of lines, so carefully find the cable connected to the left stick and attach the pressure kit to it.

- Step 03: Tighten all the lines and bolts correctly so the pressure doesn’t leak again.

- Step 04: Under the seat, you will find a dial that increases the pump pressure. Increase the pressure to 6000 psi. Seal everything and run the machine. Your stick and swing should work properly now.

The price of a pressure-checking kit should be around $30.

Note: Buy a service manual that costs only $15. It will make your work way more manageable.

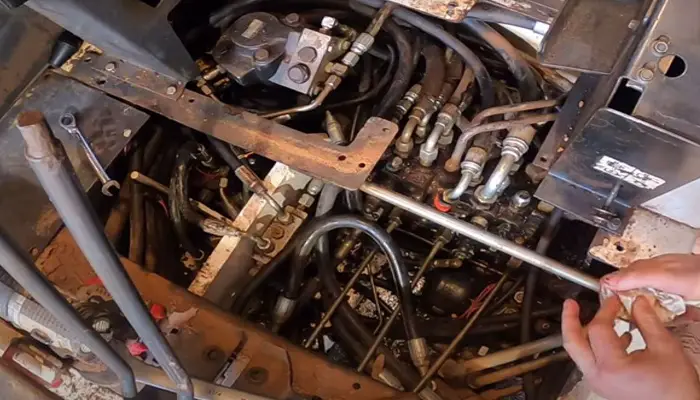

4. Hydraulic Leak Fix

To fix the problem, you need to find the source of the leak. Bobcat 331’s oil lines and hydraulic pump are under the rear, so the work gets more manageable if you pull up the machine with a lifter to work underneath. Here’s how to fix the issue:

- Step 01: Lift the excavator well enough so you can work under it. Then wait a while to see where most of the oil comes from.

- Step 02: Clean the bottom area and remove moisture from the lines.

- Step 03: You will find the oil lines connected to the engine under the seat beside the side hydraulic lines. The bolts that connect the lines must be loosened.

- Step 04: Tighten the bolts with a wrench. That should stop the leak. Even if that doesn’t work, buy an oil pump seal and put it in the middle of the connector.

Connector seals don’t cost much. You can find them at any hardware store for around $10.

5. Bucket Stalling Solution

Bobcat 331 has a limited weight lifting capacity between 6500 lb and 6700 lb. Whenever you cross that limit, the sensors detect it to shut down and lower the lifting wing so the machine doesn’t get damaged or flip aside.

Technically, it is a safety feature. So, avoid extra weight. There is no hardware fix for this problem. You should carry less to avoid this problem. Extra weight is also harmful to the bearings.

The lifespan decreases because of heavy lifting. So, lift a little less each time, and the machine should work fine. Lifting less weight will cost you time, but it will save you a lot of money.

6. Replace the Fuel Shut-off Solenoid

When your fuel solenoid has a problem, your machine will run but shut down after a few seconds. The display will show an error and won’t start again if you don’t change that part because the fuel solenoid is the primary key to starting or ignition.

To solve that problem, the manual says to replace the damaged fuel shut-off solenoid with a new one. Here are the steps:

- Step 01: Locate the fuel solenoid. It should be behind the excavator, above the exhaust lines.

- Step 02: Detach the old solenoid from the fuel line and cut the wires. Don’t forget to turn off the excavator.

- Step 03: Put the new fuel shut-off solenoid back in place. Join the wires and connect the line. Your machine should start now.

A fuel shut-off solenoid is easy to find online. It starts at $39.95. Suppose you are having trouble locating the fuel solenoid. But a service manual for $15 will make your work easier.

Frequently Asked Questions (FAQs)

What to do when Bobcat 331 won’t start?

There are several reasons for that. One common reason is that the engine is not receiving sufficient fuel due to clogged lines or the fuel got hardened somewhere. To fix this, you need a block heater to ensure the engine gets enough fuel for ignition.

How can I prevent Bobcat 331 hydraulic leaks?

Precaution is the best prevention method. Check your Bobcat 331 excavator regularly to keep the hydraulic pressure in hydraulic balance. Excavators need high maintenance, so try to check the connecting bolts and tighten them often. Also, avoid lifting anything overweight; that can damage the pumps.

Why did my Bobcat 331 drive wheels suddenly stop?

It can happen for various reasons, but the most common reason is a clogged case drain or air filter blockage. Another common cause is shorted wire, which can occur because of rough movement. Try to replace the filters every 250 operating hours; the machine should work fluidly.

How can I fix my shorted wire to restart my Bobcat 331?

Shorted wire causes the excavator to shut down the excavator and not restart. This can be a critical problem, so we suggest you go to an expert. If you know about machines, buy a repair manual and an amp fuse. Test the wire and replace it. It should fix the problem.

What is the Bobcat 331 pump problem?

The Bobcat 331 can lose all hydraulic pumps because of a gear pump problem or the engine not receiving enough fuel. The gear pump stops all the other mechanical blade controls, preventing machine work. It can also be an issue if it has a piston pump.

Conclusion

Try the methods above if you are confident enough because if you don’t have much knowledge, don’t touch any, and you may make the condition unacceptable. Bobcat 331 is a complex excavator because of its lightweight feature.

Repairing anything on this may not seem easy, but they might rip you off with new part prices if you go to the dealership first. You can help yourself with awareness. If you are cautious about what is happening with the machine, you will figure out the problem before it gets worse and solve it at a primary stage.

When it’s at an entry level, the solutions are more practical. Replacement becomes necessary when the part is damaged beyond repair. Save yourself from extra costs by protecting the excavator.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!