How to Fix Common Bobcat 825 Skid Steer Problems?

When it comes to skid steer loaders, the Bobcat 825 is a well-known model from the Bobcat company. The 825 looks sleek with its white finish and compact design. But unfortunately, like all other machines, the 825 is also susceptible to some common issues.

The common Bobcat 825 problems include hydraulic issues, control panel issues, engine problems, and other suspension-related issues. Fortunately, not all of these problems require garage intervention. Most of them can be easily solved following a few DIY methods.

In this article, we will explore different problems related to the Bobcat 825, the solutions, and the probable cost of repair.

What Are The Common Bobcat 825 Problems?

The Bobcat 825 is a diesel-powered skid steer loader. The compact design positions it as a mid-tier loader with an operational capacity of 1500 lbs. The loader has a tipping capacity of 3100 lbs and an operational weight of around 5780 lbs.

But these are just the common specs of the Bobcat 825. And as unfortunate as it is, users have reported several issues with their models. The most common and prominent ones include –

- The engine won’t start

- The engine glow plug won’t start

- Hydraulic System Failure

- Hydraulic Line Issues

- Engine Overheating

- Control System Failure

- De-Tracking

7 Easy Solutions for Bobcat 825 Problems

As you may have seen from the previous point, there are several issues with the 825 skid steer loader. While these might seem like a lot of issues for a single piece of equipment, the problems of the Bobcat 825 can be broadly categorized into three main heads – the engine issues, the hydraulic issues, and the control issues.

Regardless, we will talk about the problem, solution, and probable cost of each of the problems individually.

1. Engine Won’t Start: Repairing the Issue

The problem here is pretty much self-explanatory. More often than not, users of the 825 complain that the engine won’t either start at all or start halfway through without the proper pull.

Many people often mistake the problem for a cold battery but that’s not generally the case. The main issue here is the fuel system of the equipment.

Each Bobcat 825 or any other skid steer loader has three distinct parts in its fuel system – the filter, the fuel line, and the tank.

Most often, the problem of engine failure is related to the blocked fuel filter. Here’s how you can replace it.

- Step 1: Locate the fuel filter from the front hood.

- Step 2: Check for particles or debris on its surface.

- Step 3: If the surface appears to be clean, then the filter needs to be changed.

- Step 4: Remove the existing filter and replace it with a new one.

A standard fuel filter should cost anywhere between $50 to $175.

2. Fixing the Engine Glow Plug

The glow plug of the engine is the main ignition point of Bobcat 825. It is also known as the glow plug igniter. A faulty or damaged glow plug igniter won’t create the ignition for the ICE to start in the 825.

But in most cases, the ignitor doesn’t get damaged. Rather the battery on the ignitor dies. In that case, it is important to replace the battery of the ignitor. Here’s how you can do it.

- Step 1: Locate the ignitor from the front hood of the Bobcat. It should be under the main engine hull on the front end.

- Step 2: Unscrew the glow plug to reveal the battery housing.

- Step 3: Replace the existing battery with a rechargeable AAA battery or any other rated one as per the manual.

The cost of a pair of AAA batteries is less than a dollar. However, we suggest you strictly follow the battery model outlined in the 825 repair manual and go for either single use of the rechargeable battery.

3. Hydraulic System Failure: Refuel or Repair

The hydraulic system is the main operational unit of the Bobcat 825 loader. It’s literally in the name that the 825’s main function is to lift different objects. So if the hydraulic system fails, the entire equipment essentially becomes useless.

Hydraulic system failure occurs mainly for two reasons. One is the problem regarding the hydraulic fluid and the other is the hydraulic lines. We will detail the hydraulic line problem in the next part.

The main problem with the hydraulic fluid is the level of the fluid. A low hydraulic fluid level may render the hydraulics useless. Here’s how you can fix that.

- Step 1: Turn off the engine.

- Step 2: Check the hydraulic fluid level by opening the hydraulic valve.

- Step 3: Check whether the fluid aligns with the optimal mark line.

- Step 4: Refuel to the optimum level.

The price of the hydraulic fluid ranges from $10 to $15 per gallon depending on the brand. But it’s better to go with the Bobcat’s own hydraulic fluids for optimum performance.

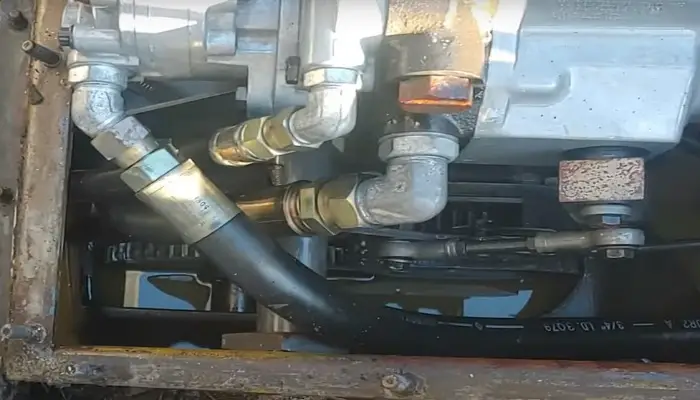

4. Hydraulic Line Issues: Repair or Replace

The hydraulic line issue is part of the hydraulic system failure problem. More often than not, the root cause of hydraulic system failure in the 825 is the lack of hydraulic fluid.

But in some extreme cases, the problem might crop out from the hydraulic line issues as well. The process of replacing the hydraulic line isn’t easy. Neither is it a DIY project.

You will need to consult the dealership or a local garage to replace the existing hydraulic lines on a Bobcat. The general steps include.

- Step 1: Locate the faulty lines.

- Step 2: Disassembling the lines. A single line can’t be replaced, rather the entire line system needs to be replaced.

- Step 3: Refitting new hydraulic lines.

There isn’t any direct cost information on the hydraulic line replacement. The relevant garage or dealership will be able to provide a quote based on the severity of the issue.

5. Overheating Issue of the Engine: Check and Clear The Radiator

There is nothing more frustrating than seeing engine overheating issues on the bobcat 825. This causes the engine to make throttling noise all the while pushing the engine performance down.

Using the engine at a constant overheated temperature might also cause the engine to blow out.

The engine heating problem is mainly caused by two problems – one is the coolant and the other is the dirty radiator. Here’s how you can solve them both.

- Step 1: Check for the coolant level on the front bonnet.

- Step 2: If it’s below the marked level then get it filled.

- Step 3: Check for the engine radiator which is generally situated on the midway front of the engine.

- Step 4: If it is dirty, remove it and get it cleaned. You can also get the radiator replaced if it has been in use for a long time.

The price of the engine coolant ranges from $10 to $15 per gallon depending on the brand.

6. Control System Failure: Restructuring the Connections

The control system is another breakpoint of the Bobcat 825. It basically causes the entire control dash to go dark and powerless.

That means it becomes impossible to control the joystick or move the equipment around or access the hydraulics.

Disconnected lines or loose loader connectors are the most frequent causes of control system failure. Here’s how you can fix them.

- Step 1: Open the dash and locate the connectors.

- Step 2: Tighten any loose connection points or socket joints.

- Step 3: Check for the hydraulics operations

- Step 4: Refit the hydraulics power pushers

The control system failure doesn’t require any major interventions unless it is a total internal failure. In that case, you will have to consult with the dealership or garage.

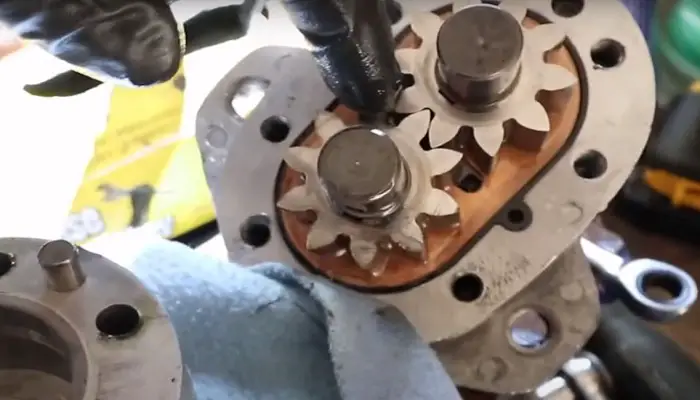

7. De-Tracking Problem: Take It To The Mechanic

De-tracking isn’t really all that common in the urban use case of the Bobcat 825. However, it is still an issue and might render the equipment useless if not fixed properly.

There are several reasons why de-tracking might occur including the spring tension, inaccurate installation of the rubber track, worn sprocket, and track adjuster leakage.

Unfortunately, there isn’t much to do if the problem pertains to de-tracking. The only plausible solution would be to take the machine to the dealership or a garage and get a quote on the repair cost.

Frequently Asked Questions (FAQs)

Now that you know all the common problems and probable solutions, let’s move on to some frequently asked questions regarding the Bobcat 825 and its problems.

What engine is the Bobcat 825?

The different model numbers of the Bobcat is the prime differentiator between equipment. The Bobcat 825 specifically has a diesel-powered 38-hp engine.

What hydraulic fluid should be used in a Bobcat 825?

Any kind of hydraulic fluids and oils can be used in the 825. It can support any brand. But Bobcat recommends that you use their self-branded products including hydraulics fluid and oil.

How do I know if my Bobcat has high flow?

If your Bobcat has high flow, it should have a dedicated button in it. Some older models also have a similar button but that doesn’t do anything. If you press the button and it turns green, then the high flow is present in your Bobcat.

How long does the track last on a Bobcat 825?

Bobcats are basically heavy lifting equipment. Needless to say, the pressure on the track is always very high and they don’t generally last as long as other lightweight equipment. The track on a Bobcat 825 generally lasts anywhere between 1200 to 1600 hours of use depending on the terrain.

How often should I grease my Bobcat?

It’s better to grease your Bobcat at regular intervals. Greasing the equipment at a regular interval ensures that the hydraulic parts operate smoothly without any hiccup. The ideal duration between every greasing should be 10 hours at best. .

Conclusion

To wrap things up, the problems regarding Bobcat 825 aren’t all that uncommon. Also, the number of problems isn’t less as well. But as things stand, most of these problems can be easily fixed with minimal cost.

Though some problems like the hydraulics line and the de-tracking require garage visits and higher run-down costs. Beyond that, it isn’t all that difficult to use and maintain a Bobcat 825.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!