How to Fix Common Bobcat M371 Skid Steer Problems?

Skid steer loaders or SSLs are highly used for landscaping and other industrious tasks. So, various models of skid steer loaders have been invented and are available on the market. Among them, the Bobcat M-371 is the most ancient and popular one.

With the attachments available with this SSL, it has become versatile and suitable for any kind of task. Nevertheless, some issues may often come with this skid-steer. The most common Bobcat M-371 SSL problems include engine failure and hydraulic malfunctions.

So, how to fix common bobcat m371 problems? Though problems are very common to face, you can easily solve them with some simple solutions. In this article, we’ll look at some common problems and solutions of M-371 Bobcat SSL.

What Are The Common Bobcat m371 Problems?

Bobcat M-371 skid steer is manufactured by one of the most reputed and ancient automobile companies in the world named Bobcat.

But you will eventually face various types of maintenance issues while using a Bobcat m371. Below are some of the most common Bobcat m371 problems that you may face:

- The engine doesn’t take start

- The fuel system isn’t functioning

- Corrosion

- Steering problems

- Faulty hydraulic system

- Unusual noise or vibration

6 Solutions For Bobcat m371 Problems

Normally, a Bobcat M-371 can run into various problems like other heavy equipment. But fortunately, each problem has an easy solution too. Below are the 6 most common problems and solutions for bobcat m371:

1. Engine Issues: Inspect the Engine Components and Repair them as Necessary

The most common problem you may face with a Bobcat m371 is that the engine doesn’t run properly. In most cases, the most possible reason for this kind of problem is a faulty fuel system.

So, start by checking the fuel system and take the necessary steps to fix the problem if you find it bad.

The engine can also break down if the throttle cables are detached from the throttle body. So, attach them tightly to the right place if you see them disconnected.

If the engine fails to start in a cold environment, the problem may be with the glow plugs. Glow plugs help to keep the combustion chamber warm.

So, if the glow plugs become loose or broken, the engine can’t warm up and fails to get started. So, check the plugs and attach them tightly if they become disconnected or loose.

The cost of repairing engine issues will range from $3,000 to $5,000. Labor costs will be between $85 and $165. Others will depend on the parts you need to repair or replace.

2. Faulty Fuel System: Replace Damaged Fuel Filter, Fuel line, or Fuel tank

A bad fuel system can cause various issues to your bobcat m371. The fuel system of a Bobcat M-371 consists of four major parts: fuel tank, fuel filter, fuel pump, and fuel line.

If any of these parts get hampered, the fuel system stops working properly and it results in malfunctioning of the engine.

It happens when you don’t use your bobcat m371 skid steer for a long time and leave it without regular servicing and maintenance. This causes accumulating dust and debris on these parts and lets them be clogged.

So, whenever the engine fails to run, or the fuel stops flowing, start by checking the fuel filter, fuel line, fuel pump, and fuel tank gradually.

If you find them blocked with dust, debris or particles, clear the blockage so that the fuel can flow to the fuel injector.

You should also make sure that the fuel injectors are working properly. If they’re clogged, proper fuel supply to the engine will be cramped.

Usually, a bad fuel system costs two to three hours of labor time. The labor cost will be between $65 and $135 per hour.

Besides, the parts will cost around $400 to $1500. So, the average cost of fixing bad fuel system issues on a bobcat m371 is between $330 and $1700.

3. Corrosion: Regular Monitoring and Cleaning

Skid steer loaders such as Bobcat m371 are usually made of heavy metal. So, when you don’t operate and monitor the body parts of the skid-steer regularly, it’s very normal that it can be corroded.

If you work in snow or any kind of fertilizer and leave it without cleaning, there can also be rust outside of the body.

Corrosion can hardly damage the important parts of the machine such as engine components, hoses, rubber seals, and even the body part.

So, clean your SSL after every single use of it and put some corrosion inhibitors in the major machine components. Regular lubricating also helps the parts prevent rust and accumulating dust or debris.

Unfortunately, if any major parts of your bobcat m371 engine glow plug or fuel system have seriously deteriorated, it can prefer a quick replacement.

4. Steering Problems: Repair the Faulty Connections and Wires in the Control System

Steering problems are those Bobcat m371 problems that are very irritating to face.

If you fail to steer your machine properly, the problem is apparently with the control system. So start by checking the wires and connections of the control system to see if they’re not loose or broken.

If you find them loose or disconnected from the place, connect them tightly to the place. Steering problems can also occur because of malfunctioning safety switches.

So, it’s a good idea to check the safety switches on the machine and replace them if they’re not functioning accurately.

On average, you should expect to pay anywhere around $550 to fix the power steering problems of a Bobcat m371 SSL.

If you need to replace the steering pump, it will cost between $100 and 4225, while the steering hoses will range from $100 to $150.

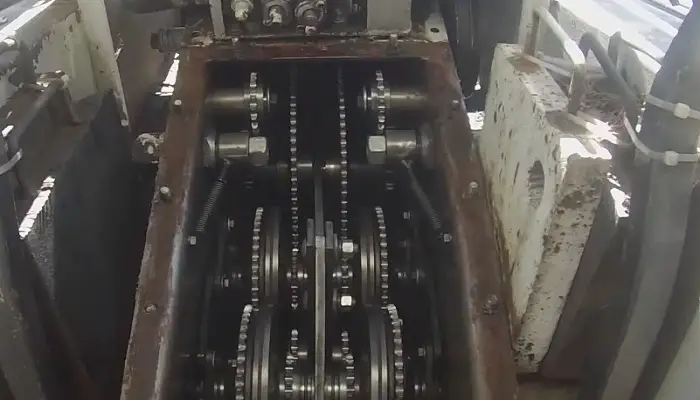

5. Faulty Hydraulic System: Ensure the Correct Level of Hydraulic Fluid

If your Bobcat M-371 skid steer loader isn’t functioning properly, the hydraulic system must be checked to see if it is working accurately.

The key reason for the hydraulic system fault is the inaccurate hydraulic fluid level in the tank. So, make sure that the skid-steer has the proper fluid level as required.

Hydraulic systems can also be damaged because of a clogged hydraulic fuel filter. It will leave off the fluid from normal flowing.

So, check the filter and unclog it if it is clogged. If the filter is seriously damaged, it’s better to replace the filter than repair it.

Additionally, it’s crucial to inspect the hydraulic fuel line if there is any leakage or loose fitting. To find out any leaks in the line, pressurize the hydraulic system and run the engine for a while.

Then visually inspect the line carefully and see where the fluid is coming out. If you notice something like that, seal the leakage or replace the line if it is quite serious.

The cost of fixing a bad hydraulic system on your Bobcat M-371 will be estimated at around $700-$1500.

If you replace the fuel pump, it will cost around $1100-$1200, while the hydraulic fuel filter can cost between $350 and $450. Labor costs will be estimated between $75 and $125.

6. Excessive Noise or Vibration: Replace the Damaged Bearings

The hydraulic engine of your Bobcat m371 may often create some unusual noise or vibration. It happens when the bearings of the engine are worn-out. Worn-out bearings can also seriously damage the engine entirely.

So, whenever you hear excessive sound or vibration coming out from the engine, check the bearings and repair them as necessary. If the bearings have become damaged badly, it’s probably a good time to replace them.

The average cost of repairing or replacing an engine rod bearing will be around $2,500 to $5,000. But if you need to replace the crankshaft bearings, it will cost between $5 and $50.

Frequently Asked Questions (FAQs)

We’ve already discussed the problems and the ways to solve them for a Bobcat m371 skid steer. But looking to know some more questions answered related to this skid loader? Here are the 4 most common questions users have about this skid-steer:

How to prevent issues with a Bobcat M-371 skid steer?

There are certain rules and regulations to follow to protect your bobcat m371 SSL from any kind of damage. Most importantly, lubricate the machine regularly and don’t start the loader from outside the cab.

How much does a Bobcat m371 skid steer loader weigh?

Bobcat m371 is usually more lightweight compared with other models of skid steer loader. The Bobcat M-371 skid steer weighs 1903 pounds or 863 kg.

What hydraulic fluid do you use in a Bobcat M-371 skid loader?

You can use a good quality AW32 hydraulic oil in your Bobcat M-371. But it’s better to use Bobcta’s self-branded all-season hydraulic fluid. It helps the hydraulic motor to run in low and high temperatures too.

Is Bobcat m371 worth money?

Bobcat m371 is a lightweight and small-sized skid steering which is more suitable for home landscaping and many kinds of industrious jobs. It is a universal skid steer with a variety of attachments. So, it has great value for the money.

Conclusion

When a Bobcat M-371 doesn’t function properly, there is no value in having a skid steer loader. Moreover, it will be very irritating to deal with those problems that come with the loader. So, it’s a good idea to be alert and try to keep the machine safe from any kind of damage.

In that case, regular maintenance and monitoring are crucial. Lubricate the running parts of the skid steer regularly and keep the fuel system and the body net clean. Don’t let the dust and debris accumulate on valuable parts of the skid-steer.

Once you notice even a single sign of skid steer issues, attempt to fix the issues whether you do it yourself or with help of a mechanic. Quick repairing will help prevent further damage to your SSL.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!