How to Fix Common Bobcat S650 Skid Steer Problems?

Construction equipment is always necessary to avoid excess hard work and physical harm to construction workers. One such reliable name is the Bobcat s650 mini skid-steer loader made from 2010 to 2017. This construction vehicle is best known for its superior handling and extreme stability.

However, the Bobcat s650 has some common problems like rev-up errors, power loss, extreme engine speeds, etc. These are all common problems and come to light after a year or two of regular usage. About 90% of all Bobcat s650 mini skid-steer loaders face such problems without regular maintenance.

These problems need to be eradicated before they cause severe damage to the machine. So, you’ll be able to quickly identify the root of the problem and repair yourself or call an expert to get the job done.

What Are The Common Bobcat s650 Problems?

As the machine works on sunny days and in dusty environments, these elements affect various parts of the Bobcat s650.

The models of this skid-steer loader were manufactured from 2010 to 2017 when the dust filters and heat-resistant substances were not good enough.

Once you have a general idea of how the problems occur, you’ll be done with fixing your machine in no time.

Some common problems that you might face frequently while operating a 2-3-year-old Bobcat s650 are as follows:

- Rev Up Error

- Power Loss

- Extreme Engine Speeds

- Hydraulic Clogging

- Accelerator Calibration Issue

5 Solutions For Bobcat S650 Problems

The common problems of this skid-steer loader require some simple but effective solutions.

In addition to that, many mechanical tools are necessary for the proper repair and fixes. For this reason, hire a professional if any of the solutions seem to confuse you.

1. Rev Up Error: Inlet Metering Valve Issue

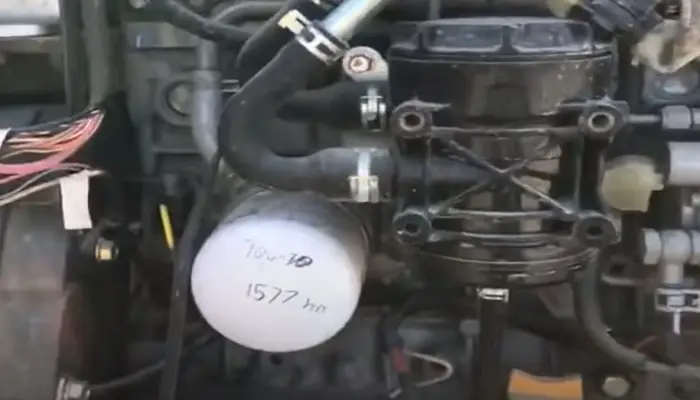

Bobcat s650 models are prone to the common rev-up error problem. As you know, the bobcat s650 uses the Bobcat D24 engine and this engine has metering rail pressure.

The problem occurs in the inlet metering valve of its metering rail pressure. When the valve fails to work, it stops responding to the user’s commands.

- Turn the key of your equipment on after turning the valve with your finger.

- The IMV (Inlet Metering Valve) should start vibrating if you don’t have this problem.

- However, it won’t vibrate if you have an IMV problem and needs to be replaced.

- Again, check the fuel filter for signs of damage or dirt.

- Clean or replace the fuel filter accordingly.

These steps should completely solve your rev-up problem. The general price of an IMV for Bobcat s650 is $3800. Again, replacing the filter will cost you about $120.

In addition to that, repairing your skid-steer loader with the help of a professional will cost you $500 excluding replacement prices.

2. Power Loss: Repair The Fuel Supply

When you experience your loader not being able to produce the regular amount of power, you should consider checking for power loss issues. Such issues are usually related to the engine’s fuel supply.

You may also face frequent power losses when you load too much on your load.

- Check if the fuel supply filter is working properly, repair or clean if damaged or dirty respectively.

- Next, patiently inspect if the fuel supply is working properly or jammed because of excess weight on your loader.

- In cases your s650 is older than 6 years, start putting less weight on it.

- If the fuel tank appears dirty, flush it out thoroughly, and refill the fuel tank.

- Inspect for air pockets in the fuel supply and repair the leaks before filling the tank.

When talking about the repair costs and expert fees, it’s quite less. You can clean the fuel tank using household materials but calling an expert will cost you about $300.

Meanwhile, replacing fuel filters will cost you about $150. You should keep more cash on hand for repairing leaks as well.

3. Extreme Engine Speeds: Reset The Loader

You’ll sometimes feel like the engine is providing more power than usual. Although this might seem great, the efficiency stays the same while your engine loses lifespan and fuel dramatically. You can identify this problem if you receive more rpm than usual.

- This might occur because of an error code in your machine. Open the HUD.

- Enter the reset code to reset the loader. You’ll get the reset code along with your s650’s manual.

- Once the code is accepted, wait a few minutes for the machine to reset codes to default.

- Check the rpm of your loader for optimal performance.

- If the engine is showing extreme speed problems again, reset it again.

As this is a common problem for Bobcat s650 models that have aged a lot, you’ll be dealing with this problem quite a few times every month.

4. Hydraulic Clogging: Inspect And Repair The System

Whenever your Bobcat s650 starts to lose efficiency, you should always check the hydraulics first.

Due to the liquid not being able to circulate through the whole system properly, the different parts of the loader begin to clog. As a result, hydraulic clogging takes place.

- As a quick identification, rub your fingers against the mechanical parts of the engine for dryness or wetness.

- If it’s mostly dry, you have identified the problem and the hydraulics needs repairing.

- Check the belt of the hydraulics and check for any wear and tear. Tighten the belt.

- Next, find the bad fitting or leaks in the hydraulics lines.

- The leaks are mainly identified as pinhole leaks, repair them accordingly.

- Check if the hydraulics chamber opens and closes properly.

You should be free from this common problem if you follow the steps. Remember to wear safety goggles and gloves while conducting this repair.

If you decide on hiring an expert, you can get the job done for about $600 including the expenses of the repairing part.

5. Actuator Calibration Issues: Adjust The Actuator

Due to cold weather and lack of usage, your Bobcat s650 will start having actuator calibration issues.

This problem will slowly spread to the engine and driving large machinery with inaccurate controls is already a big life risk.

Follow these steps to easily identify and adjust or replace the actuator parts as necessary:

- Start the machine and press the green operating button.

- Hold both joysticks towards one another and turn the operating button and machine off.

- Next, turn them back on while holding the joysticks in the same position.

- Then your ACS button will light up, hold it down and write down the code it will give you.

- Actuators should be calibrated if two dashes of two-digit numbers show up.

Now regarding this problem will occur now and then, you should make a habit of recalibrating your actuators every time you want to use your machine.

As this problem doesn’t need any repairing or replacing, you don’t need any money to solve the issue.

Frequently Asked Questions (FAQs)

People using Bobcat s650 have been facing problems since their manufacturing began in 2010. Some of these problems are complex and require intensive repair. However, some of these problems are simple repairs and are asked by the community frequently. They are:

Why is the IMV of my Bobcat s650 vibrating periodically?

IMV (Inlet Metering Valve) is a tool that needs to vibrate continuously to receive the user’s commands and work properly. The real problem occurs when it stops vibrating or vibrates periodically and needs to be replaced.

Does the loader arm of Bobcat s650 need to be manually oiled and maintained?

No, the loader arm has no problems and gets oiled by the machine from time to time. Just remember to put sufficient oil in the oil tank.

Do I have to change the hydraulics system if there are 2-3 leaks in the carriage pipe?

No, 5 leaks are the highest number of leaks you can get before you must change the hydraulics pipes only. You can repair the leaks with industrial tape and lower the pressure of the liquid.

How do I know if my Bobcat s650 loses efficiency?

Bobcat s650 has a bad reputation for low efficiency in the market. Anyway, you can identify the exact loss of efficiency by the amount of power your engine is generating and how much load the machine can take at once.

How often do I need to change the oil type of Bobcat s650?

Bobcat s650 has a balanced body and engine which requires you to change oil type every 6-8 months. Premium oil works best on this machine, but other oils work fine too.

Conclusion

Construction equipment as big as Bobcat s650 is your lifelong friend. These machines last for over 40 years and don’t rust that easily. So, you must help your friend fix the common problems they will have.

May it be from faulty parts or old age, you are bound to face the problems mentioned above once in your machine’s lifetime. These machines are not working tools but powerful objects that can provide you with money as well as a safer workspace.

So, it’s always good to know about the few common problems you’ll face when using the Bobcat s650. Now that you’re aware of them and know how to identify these problems, you’ll be done with their fixes in a jiffy. Have a nice day!

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!