How to Fix Common Bobcat S750 Skid Steer Problems?

Bobcat S750 skid-steer loader will offer you a top-notch performance in landscaping, nurseries, construction, and other applications. With many modern features, you can expect a great user experience from it. Still, the users experienced some issues with this model.

There are several Bobcat S750 problems you might experience during the operation. For instance, not moving forwards and back, regeneration issues, weak hydraulics, Power losses during operation, etc. This problem can occur at any random time.

However, the good news is there is a solution for every particular issue. If you are ever stuck in the middle of your work with your S750, worry no more. In this article, we will discuss how to fix common S750 problems.

What Are The Common Bobcat S750 Problems?

When you face any issue with your loader, it certainly wastes your valuable time. So, you should solve any issue whenever you encounter it.

Knowing the troubleshooting techniques will help you to solve issues faster. Common Bobcat S750 issues that you may experience are mentioned below.

- Not moving forwards and back

- Regeneration issue

- Weak hydraulics

- Power loss during operation

- Dysfunctional operate loader button

- Non-operational lift and tilt function

- Non-Operational traction function

7 Easy Solutions For Bobcat S750 Problems

Every problem of Bobcat S750 has an appropriate solution. But, you have to identify the right solution for a particular issue. Below we will discuss the solutions for above mentioned problems of this skid-steer.

1. Not Moving Forwards and Back: Check System Voltage and Solenoid Circuit

One of the common problems Bobcat s750 users may face is the loader doesn’t move forward and back. This issue can create great disappointment and might waste your valuable time. There can be a couple of reasons for this issue.

For instance, system voltage is maybe too low or high. If this is the issue you must adjust the system voltage. If you need to replace any fuse, do that to resolve the issue.

Besides, if the solenoid circuit is open or shorted to battery voltage or ground, this problem might occur.

If the solenoid circuit of your s750 loader is damaged, you should get a new one. The circuit may cost you $15 -$400 based on its type. If you replace the faulty solenoid circuit, your loader will move forward and back without any hassle.

2. Regeneration Issue: Check the Position of the Switch used for Regeneration.

The cleaning process of the gunked-up Diesel Particulate Filter (DPF) is called the regeneration process.

If your Bobcat S750 is in normal condition, it will regenerate automatically. But sometimes, you may experience a problem with the automatic regeneration process.

In that case, you will need to do the process manually. The problem may arise due to the inappropriate pressing of a three-position switch.

You can easily choose automatic regeneration or manual process by using the switch. If you are operating the machine in an outdoor spot, it is recommended to use the automatic regeneration process.

However, you need to make sure that once the automatic regeneration process is started, the cycle must be completed. If the regeneration cycle is not completed and the process is force stopped, there will be issues with the future regeneration process.

3. Weak Hydraulics: Remove Contamination and Change the Filter

Another problem you may experience while using Bobcat S750 is slow and weak hydraulics. As a result, the machine will not take even the normal load which is quite unexpected.

This kind of issue in the hydraulic system can happen for a couple of causes. For example, it can be particulate contamination, water contamination, and inappropriate hydraulic fluids.

You can also experience noise and elevated temperatures in addition to weak loading performance. You should always use recommended clean fluid in the bobcat s750 hydraulics system. It will help in preventing particulate contamination.

When it comes to removing water from the system, you need to conduct a complete drain of fluid. Another potential cause for this issue is maybe the filter is clogged.

If the filter is ruined badly, you should replace it. To buy a new filter, you may need to spend 40-100 bucks.

4. Power Loss during Operation: Replace Fuel Lift Pump

Sometimes, the Bobcat s750 tends to lose power during digging and driving. The problem increases when you operate the auxiliary hydraulics simultaneously. Many users face this issue as well. To solve the issue, you must first diagnose the problem.

There can be mainly two reasons for this problem. Firstly, it can be the fuel lift pump that is unable to pull enough vacuum. If it is your case, you need to replace it.

You can easily buy a new fuel lift pump for your s750 Skid Steer Loader from a local store or online shop. You can buy it for $32-$80. The price varies based on the model, brand, and overall product quality.

Secondly, if the drive belt tension is not perfect, this problem may still exist. In that case, you need to check the drive belt tension properly. If it is loose or slipping, you need to adjust it perfectly to solve the issue.

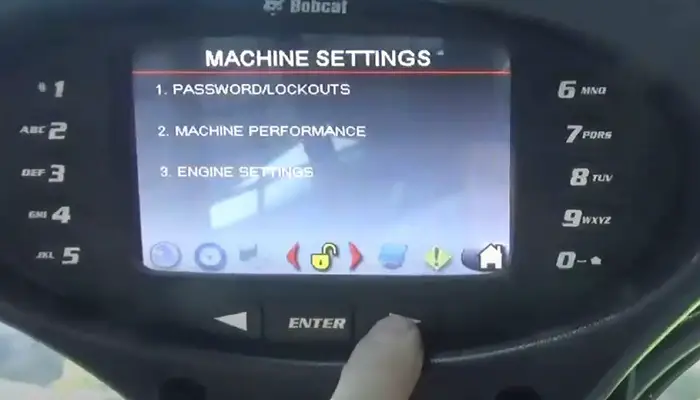

5. Dysfunctional Operate Loader Button: Fix the Bad Connection

Suppose, you are completely ready to do your task with your Bobcat S750. But, when you press the operate loader button, it is not working. This issue also happened to many users. There can be multiple reasons for this.

However, the main reason for this issue is most probably a loose or bad connection in wiring and fuses. So, you have to identify the main cause first. This can happen for a bad connection.

You can start by checking the relay and fuses in the area where your feet and back panel are located in the s750 Skid Steer Loader.

You will need to remove the cover to check the connections. If there is a bad connection, you must fix that to solve the issue.

6. Non-Operational Lift and Tilt Function: Refill Fuel Tank or Fix Valve Output Circuit

Ever wondered what could be the most common issue that Bobcat S750 users might experience?

It’s the problem with the lift and tilt function of the machine when it becomes impossible to move the bucket. If you ever face a problem in the future, first check the fluid level of the engine.

If the tank is low in fuel, this problem can happen. In that case, all you have to do is refill the tank. However, there can be other causes as well. For example, this lifting and tilting issue can happen due to a bad solenoid.

In a broad sense, if the valve output circuit of s750 loder is open, shorted to battery voltage or ground, the lifting and tilting function will not work properly.

To solve the issue, you need to fix the valve output circuit. If it is damaged somehow, you must replace it with a new hydraulic lock valve. It will cost you around 60-70 bucks to get a new one.

7. Non-Operational Traction Function:

There is no denying the fact that the traction function in a skid-steer will help you to get excellent ease of operation.

Sometimes you might experience in your Bobcat S750 that the traction function is not working.

Some causes for this issue are the opened valve output circuit, the circuit is shorted to battery voltage or ground.

Besides, if the s750 loder’s controller is not grounded at all or grounded intermittently, this traction issue can also occur. When it comes to solving the issue, you need to find the bad solenoid and replace it.

For instance, if the problem is in the valve output circuit, you must fix it. You should also replace the hydraulic lock valve if necessary. The cost for a new valve can be $60-$70.

Frequently Asked Questions (FAQs)

Although you already know some common troubleshooting techniques for this model. If you have more questions, explore the FAQ section below.

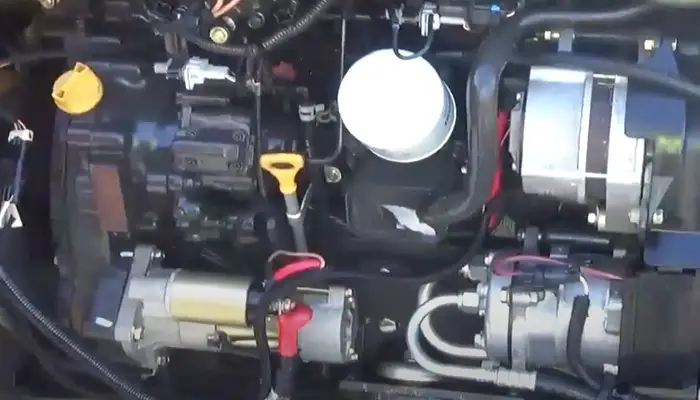

What engine is in Bobcat S750?

When you talk about the engine of S750, it is a tier 4 compliant Bobcat 3.0L engine operated by diesel. However, if you don’t use diesel particulate filtrate (Diesel Particulate Filtrate (DPF), you can skip the regeneration process.

How wide is a Bobcat S750?

The height of the machine is 81.3 inches. The width counting on the bucket is 74 inches. When it comes to the length of the bucket, it is 141.6 inches. The width of this machine is quite perfect to give you a great user experience.

How much horsepower is a Bobcat S750?

Horsepower of a skid-steer determines its overall capacity. In Bobcat S750, you will get 85 horsepower.

How much can an S750 Bobcat lift?

The overall weight of this skid-steer is 8750 pounds. It can lift to 11 fits if you consider the vertical lift. The 85-horsepower turbo diesel engine makes this lifting possible.

Conclusion

From a powerful engine to excellent lifting capacity, Bobcat S750 is an excellent skid-steer. No doubt, you can use it to serve different purposes. However, that said, many people already have experienced different problems with this model.

However, it is not the end of the road. There are solutions for every problem of this excellent Bobcat model. In this article, we discussed the solutions to some common Bobcat S750 problems.

We hope it was helpful and that you will be able to troubleshoot these problems conveniently in the future. Just make sure that you want what to do and how to do it. You can always seek professional help when you are stuck somewhere.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!