How to Fix Common Bobcat 642B Skid Steer Loader Problems?

The Bobcat 642B Skid Steer loader is a heavy-duty machine to get your work done on small construction sites, making roads, and many more. As these machines go through intense labor throughout the day, they ought to suffer from some problems over time.

Some common Bobcat 642B problems include drive motor failure, issue with hydraulic pump loader, and the engine generating squeaky noises. There can be a few other minor problems that your loader can suffer from. But, the good news is most of these issues are easily solvable.

Thus, if you are looking for ways to fix Bobcat 642b problems, you are in the correct place. In this guide, we discuss all common problems faced by this loader and its solution.

What Are The Common Bobcat 642b Problems?

If your skid steer loader stops in the middle of work or its performance is not smooth, you can have a tough time finishing your work. So, it is important to know all about these common problems.

- Problematic Drive Motor

- Faulty Hydraulic System

- Engine making squeaky sounds

- Excessive Smoke coming out

- Clogged case drain filters

6 Easy Solutions For Bobcat 642b Problems

If you have read so far, you already know about the problems that Bobcat 642B can suffer from. But, you might be wondering how to fix these issues.

Fixing them is quite easy, especially if you have some mechanical knowledge about tractors and loaders.

1. Change Oil and Damaged Bearings

The drive motor is one of the most important parts of these skid-steer loaders.

Because of this, the drive motor in your 642B skid-steer experiences strong pressure on a regular basis and has a significant likelihood of being broken.

The main reason for damaged drive motors is bearings, which need to be changed frequently along with the oil. If you do not change them on time, then your drive motor will frequently become faulty.

So, you should change the oil after every 500 hours of use and make sure to check the bearings for any damage. If they are damaged, replace them with new ones.

The replacement process can be confusing, so we recommend you take your skid-steer to a service center. A good set of bearings can cost you anywhere from $44-$120 and $90-$100 for the labor.

2. Clean Clogged Fluid Filter and Refill Fluid

Your Bobcat 642B’s hydraulic system may be the cause of a wide variety of problems.

It is well known that it drives the engine that powers the skid steer’s hydraulic systems. Issues with your skid steer’s hydraulic system might arise for a variety of causes.

You will need to check a few different things to fix hydraulic system faults in your Bobcat 642B. Read below to know more.

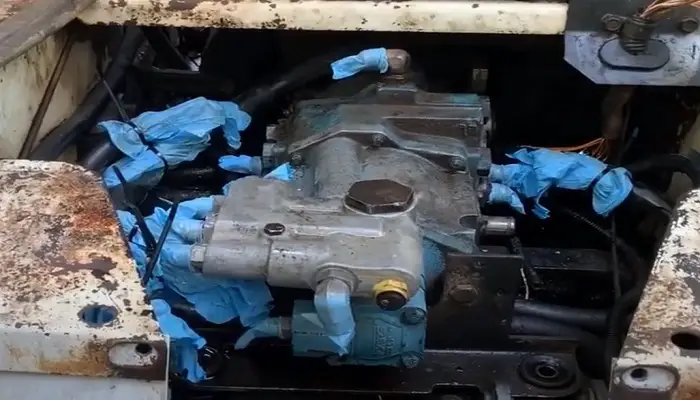

● Hydraulic Pump

The charge pump on the Bobcat skid steers is frequently a problem. When you operate the machine for a lengthy period of time, the charge pump may occasionally start to fail.

Check to see if the belts are secure; if not, make sure they are. However, you will need to replace them if they are worn out.

● Check Fluid Level

All of the moving parts in the hydraulic system are kept well-lubricated by the fluid within.

However, if the hydraulic fluid level is either too low or high, the parts will begin to produce strange noises and won’t function as they should. Maintain the fluid level at the prescribed level at all times.

● Clean clogged filters

The fuel filters filter dust and debris so that no dirt can enter inside the hydraulic system.

But, due to this, the fuel filter can get clogged up quite often. The best cure to this is to replace the fuel filter completely.

Fuel filters for Bobcat 642B are usually priced around $14.90-$30.90, and the replacement pump belt can cost between $25-$30.

3. Clean Clogged Fuel Pipes and Check for Fuel Leaks

When you are riding your Bobcat 642B skid steer loader and suddenly feel like your engine is making squeaky noises and you are observing some vibrations.

This means there is a problem inside the fuel system. Read below to know how to check and fix the fuel system.

- Step 1: Open your hood, access your fuel system, and properly check the fuel lines.

- Step 2: Look for any leaks on the fuel pipes; if you find any, you will need to replace the old fuel pipes.

- Step 3: if you see there are no leaks in the lines, you should open the pipes and clean them properly by blowing some air through them to remove any dust or debris. Put them back on, and your skid-steer should be working fine now.

4. Replace Air Filter and Head Gasket

When you observe excessive Smoke coming out from your Bobcat 642B, you have to check if the Smoke is white or black. Different colors of Smoke indicate different issues.

● White Smoke

If there is too much white Smoke from your Bobcat 642B, then it is certain that the head gasket has blown out. It usually seals air from oil and water from mixing together.

Replacing the gaskets requires skills as you will be working with tiny components. So, it is a job for a professional. The whole process can cost you around $1000-$2000.

● Black Smoke

When you see too much black Smoke from your Bobcat 642B, this means the air filter is probably clogged up due to dirt and dust. You can replace the air filters easily by yourself.

- Step 1: Open the engine cover, and the air filter should be enclosed in a box at either the right or left side of the engine. Open that box and take out your old clogged air filter.

- Step 2: Cleaning the air filter is quite bothersome, so instead, just replace the old ones with a new one and screw back the lid and engine cover. A new air filter is priced around $3-$10.

5. Replace the Clogged Case Drain Filter

We frequently forget to inspect case drain filters. However, this little part has the potential to clog and possibly explode.

Hydraulic fluid corroborates through into the final drive motor whenever the filter becomes clogged.

As a result, the drive motor in your Bobcat 642B sustains severe damage, finally exploding under tremendous pressure.

The only solution is to replace this case drain filter which must be done with the help of a professional mechanic, and the whole replacement cost can be between $60-$100.

Frequently Asked Questions (FAQs)

If you are a Bobcat 642B user you already know how good this loader is. But, still over time it faces some problems and if you are still confused on how to fix them we believe the section below will help you in this.

How often should I replace the Case drain filter in my Bobcat 642B?

It is mandatory to replace the filters in your Bobcat 642B on time. Unable to replace the filters on a regular basis can help you from other big problems.

So, the case drain filters and air filters all must be replaced after every 500 hours of running. Also, make sure to clean your fuel filters regularly.

Why is my engine making squeaky noises in Bobcat 642B?

The engine of the Bobcat 642B can make squeaky noises when the fuel pipe is clogged up and cannot provide sufficient fuel in the engine, along with a clogged air filter that restricts proper airflow.

If your spark plug is damaged, then the engine can also make weird squeaky noises.

How do I prevent hydraulic problems in Bobcat 642B?

Always do the regular maintenance of your Bobcat 642B skid steer loader and make sure to clean it properly to prevent any dust and debris buildup.

Also, make sure that fluid is on the recommended level and change your filters on time; do not wait for them to become completely unusable.

What type of engine is in Bobcat 642B?

A strong and dependable Kubota engine powers the Bobcat 642B. It weighs 3700 pounds and features a gasoline four-cylinder engine with 32 horsepower. In comparison to the more recent Doosan engines they utilize, this Kubota engine is very fuel-efficient.

Conclusion

Running into different problems in your Bobcat 642B Skid Steer Loader can be quite annoying and painful, especially during the working season. Most of these problems occur due to poor maintenance. Heavy-duty machines like this require a lot of maintenance on a regular basis.

Failing to do so can trigger many problems, as our guide discussed today. If you run into any of these issues, make sure to read our guide properly, and you can fix your Bobcat steer loader in no time.

But, if you are going to fix these problems by yourself, have a proper idea about the internals of your machine to avoid any further problems.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!