How to Fix Kubota B2400 HST No Hydraulics Problems?

There are many different sizes of Kubota tractors to adapt to any farming operation. Their main job is to pull various connections and farm machinery to perform additional tasks.

Moving heavier loads and exerting more force are both capabilities of Kubota B2400 hydraulic systems. Sometimes hydraulic systems face troubles. So, what causes Kubota B2400 HST to have no hydraulics?

Many different causes can contribute to hydraulic issues. The problems include an excessively noisy hydrostatic transmission, hot hydraulic fluid, low hydraulic system pressure, leakage, sluggish operation, and many others.

Fixing these, though, is not that difficult. Some components are easily replaceable or repairable for troubleshooting. But it’s crucial to get your hydraulic system functioning again. Check this out for more information!

What Causes Kubota B2400 HST No Hydraulics?

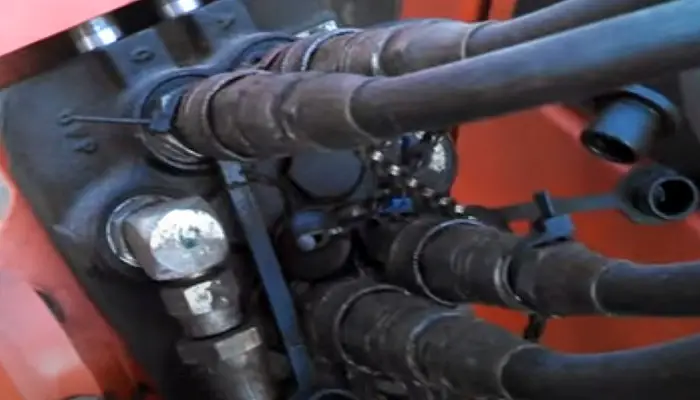

It can be challenging to identify the cause of a hydraulic system failure. An actuator, pump, valves, sump, motor, and hydraulic fluid comprise most of the hydraulic systems. Any one of these components might malfunction.

Not to ignore the additional risk of failure due to human error and poor maintenance procedures. You must understand the cause of any system failures. You ought to be able to locate the malfunction, too.

Knowing how to maintain it flawlessly in the long term is also crucial. All you should do is ensure worker security.

The failure of a hydraulic system is frequently apparent. High temperatures, poor pressure readings, and sluggish or unpredictable operation are all possible symptoms.

What are the most frequent reasons for hydraulic system failures, though? Most hydraulic problems have one of the following common causes:

- Overly noisy hydrostatic transmission

- High-temperature hydraulic fluid

- Low pressure in the hydraulic system

- Leakage

- Slow operation

5 Solutions For Kubota B2400 HST No Hydraulics

You can avoid malfunctions by keeping your equipment in good working order. It will also ensure you have the hydraulic power required for essential tasks.

By adhering to these guiding principles, you can maintain the dependability and effectiveness of your hydraulic system.

1. Overly Noisy Hydrostatic Transmission: Repair Or Replace

Many Kubota B2400 owners lament the excessive noise problem with the hydrostatic transmission. It can happen due to a bent or incorrectly modified velocity control wheel connection, an unreasonable transmitting load, low oil pressure, or tainted transmitting oil.

In addition, a broken primary shutoff valve or other dull or malfunctioning HST parts may cause the HST transmission to begin making strange noises.

Verify if the transmitting load has not exceeded the limit. Confirm the oil’s type, quantity, and contaminant status. If necessary, replace the oil and add more oil.

Load reduction is necessary. You should examine the HST’s release valve, linkage, and other internal parts. Repair or swap out the broken parts.

2. High-Temperature Hydraulic Fluid: Clean Or Replace

Any hydraulic system should never experience overheating. Numerous factors may be to blame for hot hydraulic fluid.

This excessive heat issue mainly causes unreasonable transmission load or damaged cooling elements. It might happen if your transmission fluid filtration is blocked, or you don’t have enough transmission oil. Internal leakage caused by worn-out system parts can also cause high temperatures.

Check to see if the Transmission is filled up and lighten the load if necessary. Examine each cooling element to look for any broken parts.

It would be best if you examined the transmission fluid filter’s condition as well as the level of the transmission oil. If necessary, add enough oil in addition to cleaning or replacing all the broken or defective components.

3. Leakage: Repair Or Replace

Fluid loss from even a slow leak over a period can affect performance. Most leaks are caused by deteriorated seals, broken hydraulic paths, or poor links.

Finding the leak’s origin can be difficult and risky. Never use your hand to search for a leak while the system is in operation.

Make sure your transmission fuel is at an appropriate standard. Then, check the linkage between the speed control brake and the primary control valves for their current state.

The broken part can be fixed, serviced, or replaced. If you see oil leaking from the outside, replace the damaged portion.

4. Low Pressure In The Hydraulic System: Repair Or Replace

The main reason for this problem is a low level of hydraulic fluid. It is typical for a pressure comparator hung on a pump to decrease flow at a specific pressure. Other distinctive parts that can result in reduced flow include pressure-release valves.

Filling up hydraulic fluid is a fundamental solution to this problem. You have to replace the hydraulic filter. Find the system’s leaks and fix them. Fix or replace the hydraulic cylinder. If the hydraulic pump is malfunctioning, replace them.

A hydraulic cylinder can be repaired for $50 to several thousand dollars. The cost varies depending on how many repairs are required and how big the cylinder is.

5. Slow Operation: Fix

A hydraulic system’s performance decline is frequently the first signal that it has a problem. This typically shows up as a slower operation.

It’s critical to remember that in a hydraulic system, flow dictates the response time and speed of the actuator. As a result, a decrease in speed indicates a reduction in flow.

A leak inside or outside the system can reduce flow in a piping system. External leaks, like a burst pipe, are frequently simple to locate. Since internal leakage can happen in the pump and control valve, they are more challenging to identify.

The best way to combat this problem is to keep the appropriate fluid level, an effective filter, and fix any leakage. Using the correct fluid is crucial and one of the highest quality.

FAQs About Kubota B2400 HST No Hydraulics

Kubota creates a fantastic hydraulic system. But occasionally, there are problems with this system. As a result, people frequently inquire about this. These are a few:

What would happen if air got stuck in the hydraulic system?

Aeration, foaming, or cavitation may happen when air affects the hydraulic fluid. Aeration is a problem because it causes the hydraulic fluid to deteriorate. It results in a lack of lube and harm to the system’s parts. Consequently, the seals will become overheated and destroyed.

Is it necessary to bleed hydraulic systems?

Your hydraulic cylinders won’t operate as effectively as they should if there are problems like air pockets inside the chamber. For this reason, you must bleed your hydraulic cylinders. Not bleeding your hydraulic systems could even result in disastrous mechanical malfunction.

What occurs if a hydraulic system malfunctions?

When the hydraulic pump malfunctions, dust can enter the hydraulic fluid and lead to contamination. These particles can enter a wide range of system elements. For instance, valves and actuators, resulting in harm to both these and other parts.

What occurs if hydraulic oil gets too hot?

Hydraulic fluids begin to harm your system’s parts once they attain temperatures of 180°F or higher. The seal substances start to degrade at this temperature.

Additionally, your oil will deteriorate much more quickly. A hydraulic system that consistently overheats has both immediate and lengthy consequences.

Conclusion

Hydraulic failure is possible through an inadequate level of upkeep and malfunction. The outcomes might be very costly and even more detrimental. It might even result in injury and lengthy harm. Diagnosing a hydraulic failure is crucial to determine what corrective or other steps you should consider.

We hope that our explanation was clear. Rugged terrain and heavy loads are no match for the power of Kubota tractors. Fix the hydraulic problems to maximize the use of your Kubota B2400. Enjoy your farming!

Related Posts:

- How To Adjust The PTO Clutch 1997 Mahindra Model 435D1

- 8 Solutions For John Deere Tractor Keeps Draining Battery

- Reason Your Tractor Won’t Turn Over and Solutions

- LS Tractor Won’t Start (Causes and Fixes)

- Ford Tractor Won’t Start (Causes and Fixes)

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!