Toro Zero Turn Won’t Move Forward or Reverse – How to Fix?

Dealing with a Toro Zero Turn won’t move problem can be frustrating. When this issue strikes, the once-efficient mowing companion comes to an aggravating halt, making your yard work at a standstill.

The factors like engine stalling issues and disengagement of the parking brake are the prime culprits. Also, a worn drive belt, hydraulic problems, and subpar engine operation cause unresponsive Toro zero turn.

You can swiftly get your Toro Zero Turn back in motion with some troubleshooting and maintenance. Thus, making yard care frustration-free once more. Let’s learn how you can do so.

Toro Zero Turn Won’t Move – Reasons & Solutions

Uncover why your Toro Zero Turn stalls and find effective remedies in this section, ensuring a smooth mowing experience.

1. Engine Stalling Issue

Frequent engine stalling can lead to sudden stops during operation, posing risks, especially at high speeds. This could be attributed to a malfunctioning spark plug.

Solution

Inspect the spark plug thoroughly and replace it if needed, as a faulty spark plug can impact engine performance.

Additionally, ensure proper cleaning to prevent air filter blockage, which could gradually diminish engine efficiency.

Read Also: How to Troubleshoot Toro Zero Turn Hydraulic Problems?

2. Parking Brake Disengagement

When the parking brake is engaged, the transmission cannot transmit power, resulting in the mower’s immobility.

While halted, a malfunctioning parking brake might fail to secure the mower, hindering both forward and backward movement.

Over time, the parking brake could degrade or wear out over time, potentially impacting the maneuverability of the zero-turn mower.

Solution

Ensure the brake pedal or lever is fully pressed, with no obstructions hindering complete brake disengagement. Make adjustments if the parking brake isn’t engaging or disengaging correctly.

If the parking brake is worn or damaged, consider a replacement.

Dysfunction might result from corrosion, dirt, or debris affecting the parking brake. Adequate cleaning and lubrication are essential to maintain proper operation.

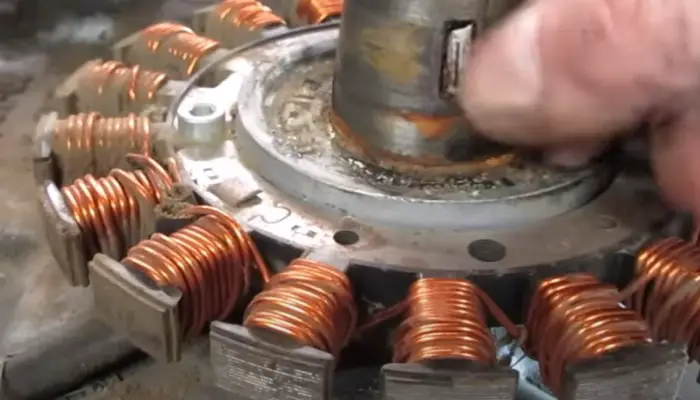

3. Transmission Malfunction

Insufficient fluid level or contamination can lead to transmission malfunction, causing the lawnmower to stop.

Over time, wear and breakage of transmission components like gears and axles can result in difficulties with the zero-turn mower’s movement.

Solution

Address the issue by replenishing or substituting transmission fluid if it’s low or contaminated. Consult the manufacturer’s guidelines for proper fluid type and levels.

Rectify or replace worn-out gears, axles, or other transmission components.

If Toro zero turn hydraulic pumps are malfunctioning, consider repair or replacement. As this task can be intricate, seeking assistance from a skilled mechanic might be advisable.

4. Drive Belt Impairment

Over time, the drive belt can experience wear or damage, leading to slipping or breakage.

A slipping or damaged drive belt can result in a disconnected transmission from the wheels, rendering the mower motionless.

Additionally, a loose or mispositioned belt can cause the drive belt to slide or disengage, preventing the gearbox from engaging with the wheels.

Correct movement issues by properly installing the drive belt in the zero-turn mower.

Solution

If worn out, damaged, or broken, address the problem by replacing the drive belt. Refer to the manufacturer for details on the correct belt type and size.

Tighten the drive belt’s tension if it’s too loose, following the manufacturer’s recommendations for proper pressure.

Ensure proper engagement by realigning the drive belt if it’s out of position, guaranteeing optimal performance.

Read Also: What Oil Does a Toro Lawn Mower Use (A Comprehensive Guide)

5. Faulty Hydraulic Pump

A malfunctioning hydraulic pump can lead to insufficient pressure to power the hydraulic motors effectively. This can result in reduced speed and sluggish performance of the mower.

If the hydraulic pump completely fails, the Toro zero turn mower will cease to move due to the absence of pressure to drive the hydraulic motors.

The hydraulic motors might not receive uniform pressure in a broken hydraulic pump. This can lead to uneven movement or increased maneuverability in one direction compared to the other.

Solution

Inspect hoses, fittings, and connections for leaks, and repair or replace any damaged parts on the hydraulic pump.

Ensure the hydraulic fluid is clean and debris-free, with an adequate level. Check for wear or damage on the hydraulic pump and motor.

Address potential issues stemming from a blocked hydraulic filter by examining and, if needed, replacing it.

6. Subpar Engine Operation

Insufficient engine power can impede the mower’s forward and backward movement.

Inefficient engine functioning may reduce fuel efficiency, causing abrupt halts or swift fuel depletion.

Solution

Thoroughly clean the fuel system to eliminate debris. If necessary, assess and replace the fuel filter.

Check and adjust the oil level if additional oil is needed to optimize engine performance.

7. Air in the Hydraulic System

The presence of trapped air in your hydraulic system can lead to sluggish or immobile movement of your zero-turn mower.

After changing the hydraulic fluid, the air must be purged from the system.

Solution

Air removal from the hydraulic system is achieved by elevating the rear drive tires off the ground for most zero turns.

Run your zero-turn, and engage the drive levers forward and backward to rotate the tires. Repeat until normal tire movement and reduced noise are achieved.

Refer to your operator’s manual for accurate air removal procedures tailored to your specific lawn mower model.

Instructions can vary not only between manufacturers but also across different models.

8. Drive Release Lever Position Issue

Zero-turn mowers have drive-release buttons, levers, or knobs to disengage the hydraulics, enabling manual pushing.

This function proves helpful when the mower halts mid-yard, requiring manual transfer onto a trailer.

Failure to position the drive release levers to “operating” will prevent the mower from moving forward.

Solution

Drive release mechanisms vary by manufacturer and model, including levers, push/pull buttons, or knobs.

Consult your owner’s manual to identify your mower’s drive release type and location.

9. Non-Hydraulic Factors Affecting Mower Movement

If issues with the hydraulic system are ruled out, consider examining these elements that might hinder the necessary fuel and air supply for your engine’s operation.

Particularly if your engine sputters or stops abruptly, investigating these factors becomes crucial:

- Battery and Charging System

- Clogged Fuel Filter and Lines

- Blocked Air Filter

- Contaminated Carburetor

Solution

- Clean the fuel lines and filter

- Remove dirt and debris from the air filters

- Keep the carburetor clean

How to Improve Toro Zero Turn Mower Efficiency?

Enhance your zero-turn mower’s performance with these guidelines:

- Keep your mower well-maintained.

- Use suitable gasoline.

- Monitor tire pressure.

- Adjust deck height.

- Regularly check the air filter.

- Assess the spark plug.

- Maintain the blades.

- Select the proper mowing speed.

- Master the mower controls.

- Practice safe and efficient turning.

- Avoid overloading.

- Ensure correct tracking.

- Refrain from mowing in wet conditions.

- Employ appropriate attachments.

FAQ

How can I tell whether my zero-turn mower’s movement problems are due to the control arm?

Inspect the control arm’s condition if your zero-turn mower experiences movement issues. Check for any physical damage, misalignments, or irregularities in its operation. If the control arm exhibits signs of wear, is loose, or doesn’t respond as intended, it could contribute to movement problems.

Can the movement of my zero-turn mower be affected by the deck height?

Yes, the deck height can influence the movement of a zero-turn mower. Incorrect deck height adjustment might lead to uneven cutting, reduced maneuverability, and increased resistance. Maintaining an appropriate deck height ensures optimal performance and consistent movement across the lawn.

How frequently should the transmission fluid level in my zero-turn mower be checked?

Regularly check the transmission fluid level in your zero-turn mower as part of routine maintenance. Aim to inspect the fluid level at least once every 25 hours of operation or as recommended in your mower’s owner’s manual. This helps ensure proper lubrication and optimal transmission performance.

Final Words

Regular maintenance is the backbone of every well-functioning machine, and your Toro Zero Turn mower is no exception. By ensuring periodic care, you can avoid Toro zero turn mower won’t move.

However, neglecting the maintenance can lead to a halt in Toro zero turn efficiency. Emphasizing maintenance isn’t just a precaution but a promise of prolonged performance.

Sometimes, despite our best efforts, issues might persist. In such cases, seeking the expertise of a professional mechanic is a prudent step. Remember, a well-maintained mower not only simplifies your yard work but also extends its overall lifespan.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!