Cub Cadet Zero Turn Hydrostatic Transmission Problems? Fixes

Cub Cadet, an American tractor brand, is renowned for its robust and efficient tractors for mowing gardens and farms. While their hydrostatic systems are highly effective, they can encounter specific issues over time.

Common Cub Cadet zero trun Hydrostatic transmission problems include system failure, fluid contamination, air contamination, overheating, and cold systems. Prompt action to the concerns is a must to avoid further damage.

Diagnosing hydrostatic transmission problems is challenging. But before panicking and making a wrong decision, there are methods to tackle the issues efficiently. The following information will help you identify the causes and solve them accordingly.

Common Causes Of Cub Cadet Zero Turn Hydrostatic Transmission Problems

Below I shared the most common hydrostatic transmission problems in Cub Cadet zero trun. Explore them carefully.

1# Contamination of Air

Air entering the hydraulic system can cause significant issues in Cub Cadet 1050 and other models. This occurs due to a faulty pump system or a breach in the system.

There are two primary reasons for this, which are:

- Aeration, where air enters through loose connections

- Cavitation, where the pump pulls and implodes air in the hydraulic fluid.

Both can lead to severe damage to the hydrostatic system. To prevent this, it’s essential to properly purge the hydrostatic system.

I shared the detailed procedure of purging the hydraulic system in the later part of this guide

2# Contamination of Fluid

One potential reason for hydrostatic system issues is fluid contamination or staleness, leading to reduced performance.

Thick fluid can cause temperature and overheating problems. To address this:

- Change the hydrostatic fluid regularly.

- Before doing so, ride the machine to bring up settled contaminants for easier draining.

- Place a container under the oil fill plug, remove the drain plug to drain the old oil into the container, and clean the screen before adding new oil.

Proper maintenance helps maintain a well-functioning mower hydrostatic system.

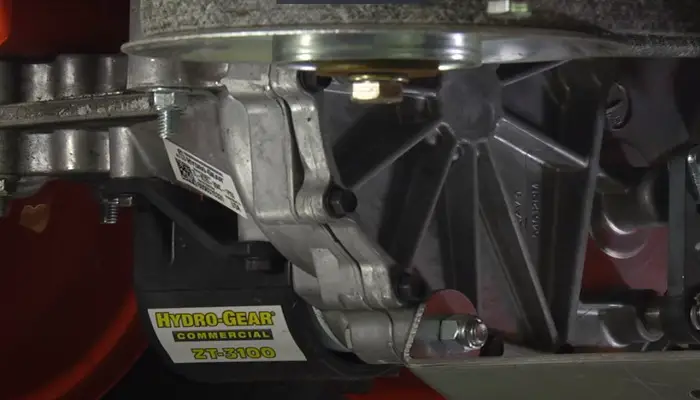

3# System Failure

Several common reasons can lead to the failure of your Cub Cadet’s mower system. The reasons include dirty cooling fins, incompatible parts, and faulty components.

To ensure the smooth operation of your mower, it is essential to stay informed about your mower’s specific details.

Also, regular cleaning of the cooling fins help you remove dirt and debris. Proper maintenance will help keep your Cub Cadet mower running efficiently and avoid potential issues.

Read Also: How To Fix Common Cub Cadet Zero Turn Steering Problems?

4# Overheated Hydraulic System

Experiencing a hot hydrostatic system after prolonged use is abnormal. It can lead to issues such as lubrication problems and fluid leaks. Heat can cause fluid oxidation, thickening fluid and building up the system over time.

Overheated hydraulic systems happen for incorrect insulation of the pump and tank.

Moreover, if you are using the hydraulic continuously on heavy equipment, the hydraulic system may overheat.

For a well-functioning hydrostatic system, addressing overheating promptly is important.

Moreover, ensuring proper fluid cooling and lubricating to avoid potential complications is crucial.

If you think that the hydraulic system temperature is increasing, check the internal temperature reading using an infrared thermometer.

Wondering which temperature range is high for a hydraulic system?

More than 180-degree F is considered as excessively high.

Regular maintenance and monitoring will help prevent any adverse effects of a hot hydrostatic system on your equipment’s performance.

5# Cold Hydraulic System

Excessive cold and hot hydrostatic systems can pose significant threats to your Cub Cadet mowers.

A cold system experiences the same thickening effect as a hot one, hindering proper heat dissipation and potentially damaging the system over time.

As mentioned, a cold hydraulic system means thick oil. As a result, oil can’t move properly through the lines.

In this case, the solution is pretty simple.

- Avoid driving your mower. Park it in a place where the temperature is warmer.

- Choose some oil additives which will help the oil to thin out and flow easily under colder temperatures.

Maintaining the hydrostatic system at an optimal temperature is crucial to ensure smooth operation and prevent any adverse effects on the equipment.

Read Also: Cub Cadet Zero Turn Pulls to One Side – Why & How To Fix It?

How to Fix Cub Cadet Zero Turn Hydrostatic Transmission Problems?

Finally, the moment you’ve been waiting for! Here are some DIY troubleshooting tips for your Cub Cadet hydrostatic transmissions.

Step 01: Purging the System

Consider purging your hydrostatic transmission if your hydraulic motor is too slow or air is trapped in the system. While there are ways to make your hydrostatic lawn mower faster, let’s focus on how to purge a Cub Cadet hydrostatic transmission.

Follow these steps for purging the hydrostatic transmission:

1. Park the Machine on Level Ground

Place the equipment on a flat surface like your car garage, and engage the brakes. Ensure sufficient oil in the system before troubleshooting.

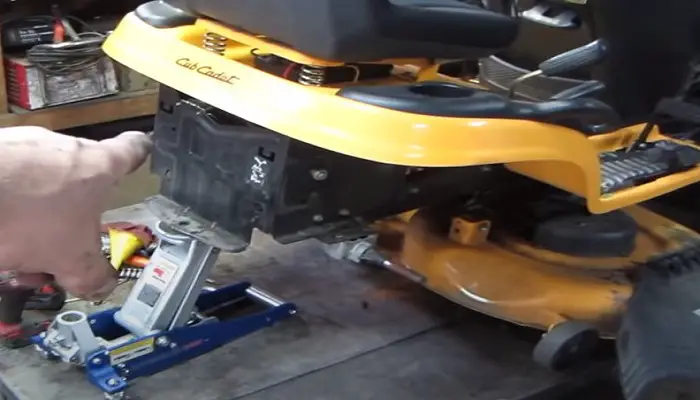

2. Disassemble the Transmission

Disengage the system, sit in the operator’s chair to access the engine, and start it.

Moving the throttle control slowly while the engine is running, detach the brake paddle/clutch, and set the motion control levers to neutral.

3. Get Rid of the Air

Push the motion control levers forward and maintain that position for a minute. Then, push them backward and maintain them for another minute. Repeat this process a few times to release air from the hydrostatic transmission.

Step 02: Clean the Cooling Fins

Cleaning the dirty cooling fins is crucial to maintain your hydrostatic transmission’s performance.

Use a brush, clean rag, or compressed air to remove dirt from the pump cooling fins. This simple maintenance step ensures optimal cooling and prevents technical problems in hydrostatic transmission.

Step 03: Examine Damaged Components

Inspecting damaged parts and replacing contaminated hydraulic fluids are essential to dealing with Cadet hydrostatic transmission issues.

For an overheating hydrostatic transmission, check the oil level, heat exchanger, motor case drain, and pump for excessive bypassing.

Inspect the system for damaged components, such as connections and hoses, and replace them.

Also, check the steering and hydraulic fluids for signs of wear and consider a replacement. Overused and old fluids can lead to hydrostatic transmission problems.

If the hydraulic fluid has lost its anti-foam additives, it won’t be practical for Cadet hydrostatic transmission. Watch a video for quick solutions to such transmission problems.

Read Also: Cub Cadet Zero Turn Moves Slow – Why & How To Fix This?

How Do You Maintain Cub Cadet Hydrostatic Transmission?

Proper maintenance will surely prolong the life of a Cub Cadet lawn mower. Here are a few maintenance tips to be followed.

Ensure Manufacturer Recommended Maintenance

Regular maintenance is crucial for Cub Cadet lawn mowers and all mowers. The environment can be harsh, so cleaning off excess debris after each use is essential.

Follow the maintenance schedule provided in the Cub Cadet maintenance guide or create a personalized one to ensure your mower’s optimal performance and longevity.

Maintain Your Limits

Maintaining your limits is crucial when using a lawn mower. Avoid pushing it beyond its capabilities, which could lead to damage and costly repairs.

Ensure you cut the grass within the recommended height to avoid spoiling the mower blades.

If your mower is not suitable for clearing your land’s size, consider upgrading to a larger one that can handle the task efficiently.

Handle Lawn Mower Transmission Properly

Ensuring the proper use of your lawn mower transmission is crucial for its longevity and performance.

Always stop the lawnmower completely before shifting the transmission to reduce potential problems and extend its service life.

This simple practice will significantly benefit the transmission and improve overall mower performance.

Properly handling your lawn mower transmission is essential for its health and longevity.

Always stop the lawnmower before shifting from forward to reverse to avoid stressing the gears and linkages.

Remember to manually disengage the transmission when pushing the mower, and use the bypass if available.

By following these practices, you can prevent many of the issues we discussed and extend the service life of your lawnmower with minimal problems and complications.

FAQ

What signs are shown by this Cub cadet hydrostatic transmission problem?

Signs of a problematic Cub Cadet hydrostatic transmission include difficulty starting the mower, rough shifting, and an inability to drive smoothly. Thickened fluid in cold temperatures may lead to poor performance and potential damage to the hydrostatic system.

Why is fluid contamination a problem with Cub cadet hydrostatic transmissions?

Fluid contamination in Cub Cadet hydrostatic transmissions is problematic because it can degrade the fluid’s quality, leading to reduced performance and potential damage to the system. Contaminated fluid may cause issues like overheating, improper lubrication, and component wear, impacting the transmission’s efficiency and longevity.

How Often Should I Change the Oil in My Cub Cadet Hydrostatic System?

For optimal performance, changing the oil in your Cub Cadet hydrostatic system at least once a year or after every 50 hours of operation is recommended. Regular oil changes help maintain the system’s efficiency, prevent contamination, and extend its service life.

Final Words

Facing Cub Cadet hydrostatic transmission problems may seem daunting, but there’s no need to worry. The straightforward solutions can be tackled with basic technical knowledge and know-how.

By monitoring the signs and symptoms of potential issues, you can easily identify and resolve any problems. Regular maintenance and attentive troubleshooting will ensure your hydrostatic system operates smoothly. It allows you to continue enjoying the efficiency and reliability of your Cub Cadet mower.

Stay proactive, and your mower will be back in excellent working condition.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!