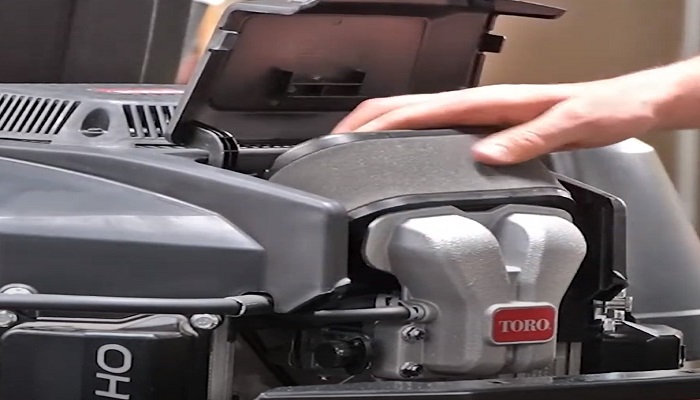

How to Troubleshoot Toro Zero Turn Hydraulic Problems?

Toro zero turn mowers are well-known for their potent and effective cutting performance. However, they can occasionally confront operational glitches. Such a problem is the Toro zero turn hydraulic problems.

This issue can manifest for diverse reasons, including air and water infiltration into the hydraulic fluid or the gradual deterioration of internal constituents. While hydraulic failure might prove exasperating, it commonly remains avoidable and manageable through systematic problem diagnosis and conscientious upkeeping.

By rectifying the problems, you can ensure the seamless operation of your Toro zero-turn mower over extended periods.

Why does Toro Zero Turn Hydraulic Fail?

Hydraulic issues impact mower performance and maneuverability. These problems can lead to reduced speed, compromised steering, or complete operational halts. Here, I looked into the explanations behind these causal factors.

Inadequate Fluid Levels

Insufficient fluid levels represent one potential origin of hydraulic issues. The hydraulic system depends on an ample fluid quantity to generate pressure and offer lubrication to its components.

When fluid levels dip too low, the pump might struggle to extract enough from the reservoir, leading to cavitation and air bubbles. Such occurrences can harm the pump and diminish hydraulic pressure.

Solution

It’s advisable to inspect the fluid levels and replenish them as necessary routinely. Moreover, adhering to your mower model’s prescribed fluid type and grade is crucial.

Blocked or Contaminated Filter

A different potential source of hydraulic troubles is a blocked or contaminated filter. The filter aims to eliminate impurities or residue from the fluid before it arrives at the pump and valves.

When the filter becomes obstructed or soiled, it can impede the fluid’s flow and lead to a decline in pressure. This can subsequently impact the mower’s velocity and steering capabilities.

Solution

Swap out the filter as outlined in the maintenance timetable or whenever its condition appears compromised. Furthermore, refraining from operating the mower in dusty or grimy environments is advisable.

Degraded or Impaired Pump

A third plausible explanation for hydraulic issues is a deteriorated or impaired pump. The pump constitutes the core of the hydraulic system, as it generates the requisite pressure to propel the motors and cylinders.

Worn or damaged pump fails to generate adequate pressure or sustain a consistent fluid flow. Consequently, the mower’s potency and responsiveness can diminish.

Solution

Routinely examine the pump for any indications of wear or damage, like leaks, fractures, or unusual noises. Additionally, adhering to the mower’s specifications and refraining from subjecting the pump to excessive loads or overheating is advisable.

Contaminated Fluid

When hydraulic fluid becomes tainted with dirt, debris, or moisture, it obstructs the smooth operation of the system.

This contamination can arise from external influences, such as operating the mower in dusty or damp environments, or internal factors, like deteriorated seals or gaskets. Regular fluid analysis and effective filtration methods are crucial in thwarting this issue.

Furthermore, air and water can provoke the system to operate excessively high or low temperatures. Therefore, further damage to internal components and decreased overall performance.

If neglected over time, this contamination can culminate in system failure. As a result, severe consequences like power loss, sluggish movement, and even total mower breakdown may occur.

Solution

Change the fluid according to the manufacturer schedule. At the same time, check the fluid condition periodically. If you change the oil after a long time, the oil may become contaminated and cause hydraulic problems.

Read Also: Toro Zero Turn Won’t Move Forward or Reverse – How To Fix?

How to Troubleshoot Toro Zero Turn Hydraulic Problems?

If you suspect that your Toro zero turn mower might be undergoing hydraulic failure, several troubleshooting measures are available to help you identify and rectify the problem. The following steps outline the primary actions to take:

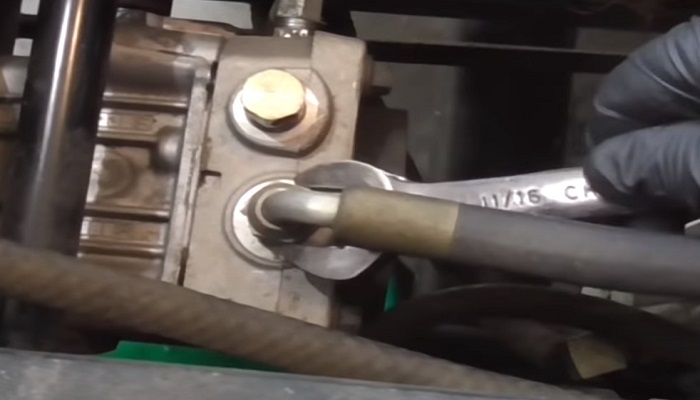

Inspect the Pressure Release Valve

The pressure release valve holds the responsibility of regulating hydraulic system pressure. A malfunction in this valve can lead to a system breakdown. Confirm that the valve is open and free from any leaks or obstructions.

Examine the Motor and Wiring

Ensure the mower’s motor is activated and all wiring connections remain secure. A malfunctioning motor or loose wiring can contribute to system failure.

Extract the Pump and Examine its Inner Components

The pump holds the role of propelling hydraulic fluid throughout the system. If it sustains damage or shows signs of wear, it can lead to system failure. Take out the pump and carefully assess its internal components for indications of wear and tear or any other potential concerns.

Assess the Hydraulic Oil/Fluid Level

The hydraulic fluid functions as the system’s vital fluid and must maintain the appropriate level for optimal operation. Scrutinize the fluid level and supplement it as needed.

Inspect All Lines and Junctions for Leakage

Leakage within the lines or at connection points has the potential to result in fluid loss, ultimately leading to system breakdown. Thoroughly examine all lines and connection points for any signs of leaks and promptly address any identified issues.

It’s essential to acknowledge that these diagnostic steps serve as a broad reference, and for precise guidance, referring to the owner’s manual of the mower’s particular model is advisable.

If the issue persists, seeking assistance from a certified technician is the recommended course of action.

Read Also: What Oil Does a Toro Lawn Mower Use?

How to Fix Toro Hydraulic Pressure Issues?

Addressing hydraulic pressure problems with your Toro mower involves several potential solutions. Consider these steps to alleviate the issue:

- Activate Freewheel Mode: Locate the bypass valves, usually situated on the hydraulic pump or close to the rear wheel motors. Refer to the mower’s manual for specific guidelines on engaging freewheel mode via the bypass valves. By doing so, you disconnect the hydraulic system, granting free movement to the wheels.

- Initiate Mower Operation: Situate yourself on the mower, initiate the engine, and ensure its smooth operation.

- Release Brake: While the engine is running, disengage the parking brake or any other applied braking mechanism.

- Cycle the Drive Lever: Gradually push the drive lever to its full forward position and hold it there for approximately 10 seconds. Subsequently, pull the lever entirely backward into the full reverse position and maintain it for an additional 10 seconds. This action aids in dissipating any residual pressure residing within the hydraulic system.

- Repeat as Necessary: If the hydraulic pressure problems persist, repeat steps 3 to 5 multiple times. Sequentially maneuvering the drive lever forwards and backward can assist in releasing any trapped pressure within the system.

Hydraulic System Maintenance

Undoubtedly, regular maintenance of the mower is the best thing to avoid problems. It can prong the lifespan of your Toro zero turn mower also. Let’s learn the maintenance tips.

- Conduct daily checks, such as verifying oil levels and ensuring secure hose connections to prevent the escalation of significant problems.

- Develop and implement a routine maintenance schedule on both a weekly and monthly basis. Address potential causes of common failures, including filters, components, and oil conditions. Diligent maintenance can significantly extend the lifespan of your system.

- Employing an infrared thermometer can simplify inspections by displaying varying temperatures across your mower in a color gradient.

FAQs

How can I identify if the hydraulic system of my Toro zero-turn mower is experiencing failure?

Indications that your Toro zero-turn mower’s hydraulic system might be encountering failure include diminished power, sluggish movement, unusual noises or vibrations emanating from the mower, or instances of leaks. If you detect any of these signs, it is imperative to troubleshoot and diagnose the issue promptly.

Can I handle the repairs on my Toro zero-turn mower’s hydraulic system on my own, or should I seek the assistance of a professional?

Although the owner can undertake specific fundamental troubleshooting and maintenance tasks, more intricate repairs or comprehensive problem diagnoses should be entrusted to a skilled professional.

Are Wear and Tear Common in Hydrostatic Transmissions?

Hydrostatic transmissions exhibit lower efficiency when contrasted with their manual or automatic counterparts. Consequently, they generate more heat while performing equivalent tasks, and dissipating this surplus heat poses a challenge. This heightened heat exposure contributes to a reduced lifespan for this particular type of transmission system.

Final Words

Hydraulic failure is a prevalent issue encountered in Toro zero-turn mowers. However, it can be avoided and resolved with appropriate troubleshooting and maintenance.

The primary culprit behind Toro zero turn hydraulic problems is often the contamination of hydraulic fluid with air and water. This contamination can lead to excessive temperature fluctuations within the system, ultimately culminating in serious long-term problems.

For effective troubleshooting of hydraulic failure, it is imperative to carry out the above-mentioned steps. Notably, consistent maintenance is pivotal in averting and resolving hydraulic issues. This entails routine oil changes, regular fluid level checks, and ensuring the overall health of all components.

By proactively undertaking the required measures to troubleshoot and remedy hydraulic failure in your Toro zero-turn mower and promptly seeking professional assistance when warranted, you can ensure the seamless operation of your mower for an extended duration.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!

![New Holland 134 Hydraulic Oil Equivalent [All You Must Know]](https://gardenerpoints.com/wp-content/uploads/2023/09/New-Holland-134-Hydraulic-Oil-Equivalent-768x480.jpg)