How to Fix Common Bobcat S130 Skid-Steer Problems?

The Bobcat s130 is a versatile skid steer loader that has an extensive diversity of skid steer attachments for its loader. Undoubtedly, it is very useful for landscaping, farming, agriculture, and any other industrious job. However, like other machinery, this skid steer loader does show some problems over time.

That said, some common Bobcat S130 loader problems include engine issues, electrical issues, or hydraulic issues. Fortunately, you can solve these problems and get back your SSL by replacing the faulty body part after diagnosing the issue.

In this article, we’ll go through the Bobcat s130 problems and how you can fix them yourself. So, let’s check it out.

What Are the Common Bobcat S130 Problems?

The S130 skid steer loader is manufactured by the world’s best-selling skid steer brand, “Bobcat.” But still, there are some common problems that often come with a Bobcat S130 skid steer. The most common Bobcat S130 skid steer problems may include:

- The engine stops working.steering problem

- Excessive sound from the exhaust

- Hydraulic cooling fan problem

- Starting Problems

- Hydraulic system failure

6 Solutions For Bobcat s130 Problems

Bobcat s130 problems are very common and irritating to get out of. So, the problem should be fixed as soon as possible. Here are the six most common solutions for Bobcat S130 skid loader problems.

1. Power Steering Issue: Check the Fluid level, Fluid Pump and Hoses for Leaks and Repair as Needed

Most often, the Bobcat s130 skid steer may experience power steering problems. The most common power steering problem is that it’s difficult to

turn the S130 Bobcat skid steer wheels.

In this case, the most potential causes may include lack of power steering fluid, leak problems, clogged hoses or a faulty power steering pump.

Start by checking the fluid level in the fluid pump, as the main reason for this problem is lack of power steering fluid.

To do so, remove the cover of the fluid pump and add more fluid until the fluid level meets the recommended fluid level for a Bobcat S-130.

Another reason for low fluid level in a s130 SSL can be an unusual leakage in the system. So, go to check if there are any leaks and fix them using power steering additives.

If there is no leakage, clogged hoses can be the main culprit. So, visually inspect if there is a clog in the hose. Once it’s clogged, it’s better to replace it with a new one than repair it.

On average, the cost of power steering fluid system repair on Bobcat s130 skid steer loaders ranges from $500 to $700.

You should expect to pay between $65 and $150 for the labor cost, while other costs will depend on the parts you need to change.

The hoses will be priced between $60 and $165, while the power steering fluid pump will cost $150 to $350.

2. Excessive Exhaust noise: Repair or Replace the Exhaust System if it has Leaked.

The exhaust system is a crucial part of a Bobcat S130 loader machine. The parts of the exhaust system are prone to rust or corrosion.

It can cause cracks or holes in the exhaust manifold, exhaust pipe or even the gasket. So, these are the actual culprits for the loud hissing noises from the

exhaust.

So, visually inspect the entire exhaust system to see if there are any leaks. If the leaks or cracks are simple to weld or seal, all you need to do is just patch up the holes or cracks.

But if the damaged part is quite rusty and cannot be repaired, you can replace the required section of the exhaust to solve this problem in your Bobcat s130.

The average cost for repairing leaks in the exhaust system of a s130 skid steer loader can be between $150 and $400. Labor costs will be estimated at around $85, while the repaired parts can cost between $65 and $330.

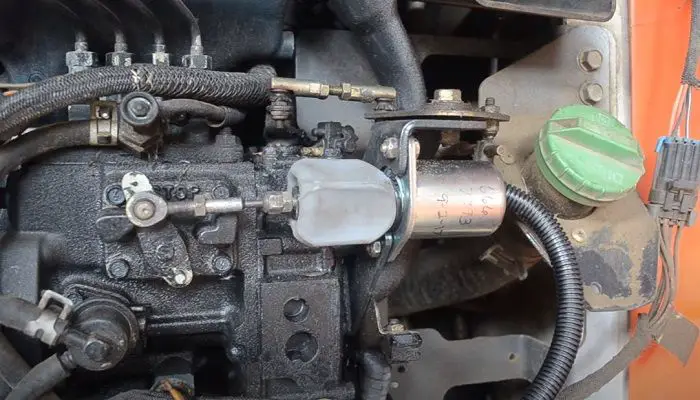

3. The Engine Doesn’t Work: Ensure that the Engine is Getting Enough Fuel

The Bobcat s130 skid steer loader will often experience the engine not working properly. It may stop starting or start stalling. The main reason for this problem is that the engine doesn’t get enough fuel to run.

Low fuel level is a sign of engine malfunctioning in a s130 bobcat machine So, inspect the fuel level and add more fuel to the tank if necessary. If you see the fuel level continuously falling, it may be because of oil leaking.

So, check the entire fuel line to see if there is any leakage. If there is any leakage in the line, it should be sealed or replaced as required.

If the engine of your s130 SSL is continuously jerking and kicking off, a clogged fuel filter could be the main culprit. Check the fuel filter and replace it if it is completely blocked.

To remove the fuel filter, disconnect the hoses and bolts that hold the filter in brackets. Once the filter is removed, install a new one so the fuel can flow properly.

In general, the cost of fixing bobcat s130 skid steer engine issues will be between $160 and $1160. The labor cost will be around $100 per hour to diagnose the problem and fix it.

In this case, if you replace the fuel filter, the price will range from $15 to $70, while the fuel pump will cost $350 to $440.

4. Hydraulic Cooling fan Problem: Check the Electrical Connections and the Fan itself

The hydraulic cooling fan (also known as the radiator fan) is an important part of the Bobcat S130 skid steer. It keeps the engine cool during high temperature or low speeds.

The components of the fan or the fan itself are prone to wear out as time goes by. So, it’s normal that the cooling fan may often stop functioning properly.

However, the major causes for the Bobcat s130 cooling fan problems are blown fuse, bad wiring or connectors, broken radiator fan, damaged radiator fan relays etc.

So, when you find the radiator fan is faulty, start by checking the fuse. If the fuse is blown, it should be replaced with a new one.

If the fuse is fine, the next suspect could be bad wiring or connectors. So, inspect the entire wiring of the hydraulic cooling system of your Bobcat S-130. If the wiring is broken, replace the damaged section of the wiring with a good one.

A faulty cooling fan motor in a s130 skid steer can also be the reason for the radiator fan malfunctioning. So, check the motor and replace it if you find it worn out.

The cooling fan controller sensor should also be checked. If the sensor is broken, the controller unit will fail to start the fan. So, replace the sensor, if it doesn’t work properly.

The broken blades of a radiator fan can also cause it not to come on. So, inspect each blade of the fan to see if there are any cracks or breaks. If it is broken, replace it with a new blade.

Faulty cooling fan relay can be a major culprit for this problem in your s130 bobcat skid loader. So, don’t forget to check the relay and changing it if necessary.

If you have to replace the hydraulic cooling fan of your Bobcat S130, it will cost anywhere from $160 to $627. Otherwise, the other electrical parts will cost from $300 to $850. The labor cost is between $150 and $1060.

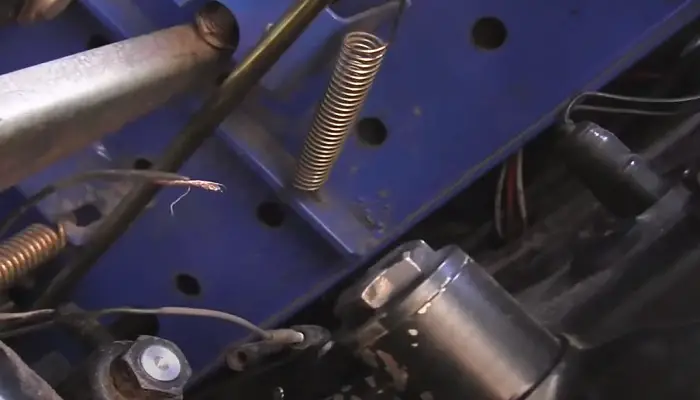

5. Starting Problem: Look for the Electric Faults and fix them as Necessary

One of the most common problems of a Bobcat S130 skid steer loader is that it fails to get started. If the engine and the fuel system are working fine, it is probably the case of electrical issues with the machine.

The most common electrical malfunctions include a bad starter, dead battery, and loose or damaged spark plugs. So, when your s130 SSL fails to come on, the first suspect will be the starter.

If the starter doesn’t make any “click” sounds, check the starter and verify if it is damaged or bad.

The starter should be replaced, if you find it faulty. But if the starter is nice but the Bobcat s130 loader doesn’t run, a dead battery can be the main culprit.

So, inspect both terminals (positive and negative) of the Bobcat S130 SSL and see if the cables are connected. If any of them are disconnected, reconnect the cable and try to start your s130 skid steer again.

If it isn’t still working, check the battery to see if there is any power. After testing, if you find the battery is dead, attempt to jump start the Bobcat s130. If it refuses to start again, it means the battery needs to be replaced.

The average cost of repairing electrical issues in a s130 bobcat SSL will rack up between $200 and $1200. If you just replace a dead battery, it will cost approximately $150 to $400.

But if you need to rewire the wiring system of the loader, it will cost up to $1300, including the labor charge of $100 per hour.

6. Hydraulic system Failure: Verify the Hydraulic system Parts and Replace the Required

Hydraulic system failure is very common for a Bobcat S130 skid steer loader. There are various causes, such as improper hydraulic fluid level, clogged hydraulic fluid filter or fluid pump that can damage the hydraulic system.

An accurate fluid level is crucial for running the hydraulic system properly. If it is overfilled or underfilled, the Bobcat s130 skid steer will fail to function and run. So, check the fluid level and add or remove more fluid as necessary.

If you see the fluid level suddenly drop, it may be the result of unusual leaks in the hydraulic line. So, inspect the entire system if there is any leakage. The hydraulic system on a Bobcat S130 also fails because of a blocked fluid filter.

So, check the fuel filter to see if it’s functioning properly. If it is clogged, replace the filter with a new one. It’s better to replace the filter than to repair it when it’s clogged.

If the filter is working fine, the main culprit could be a damaged fluid pump. So, verify the fluid pump and replace it if necessary.

The cost of fixing hydraulic system problems mainly depends on the parts you have to change.

A new hydraulic fluid filter will cost $15-$35, while a hydraulic fluid pump will cost $198-$400. Labor costs for this replacement will be estimated at $100-$150.

Frequently Asked Questions (FAQs)

Do you want to know more about Bobcat S130 skid steer loader problems? Well, here we’ve come up with more questions and answers related to Bobcat S-130 SSL issues.

What attachments can a Bobcat s130 skid steer load?

A Bobcat s130 skid loader comes with a wide range of skid steer attachments on its loader. The most used skid steer attachments on s130 Bobcat skid loaders include buckets, 4 in 1 buckets, grapple buckets, brush cutters and more.

What do you use a bobcat s130 skid-steer for?

Bobcat s130 skid loader is usually used for landscaping, agriculture and industrious jobs. More specifically, it is very useful to move heavy materials and load them into a dump truck.

How much does a Bobcat s130 skid loader cost?

A brand new Bobcat S130 skid-steer will cost 24,900 US dollars. But if you don’t have enough budget, you can buy a used Bobcat S130 skid loader for $10,000.

How many hours does a Bobcat S130 skid-steer last?

Basically, a Bobcat S130 skid steer loader lasts from 5000 hours to 8000 hours. But this lifespan can be increased by proper maintenance and servicing.

Conclusion

Throughout the article, we’ve already discussed the common Bobcat S130 skid steer problems and their solutions. So, we hope that now you have enough knowledge about how to fix Bobcat S130 problems?

But trying to prevent the problems is more crucial than fixing them with money and hassle. So, clean your s130 skid steer after each use and lubricate the moving components of the SSL.

If you have tried all the fixes listed above but the skid loader is still malfunctioning, the problem may be somewhere else. Don’t forget to check the safety switches, alternator, wiring harness, and fuse box.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!