How to Fix Common Bobcat CT1025 Compact Tractor Problems?

The Bobcat CT1025 is a superb vehicle for farm/fieldwork. This great tractor will give you some advantages over most tractors. But you’ll face some issues if you’re using a CT1025 for a long time. Have you ever thought about what the common Bobcat CT1025 problems are?

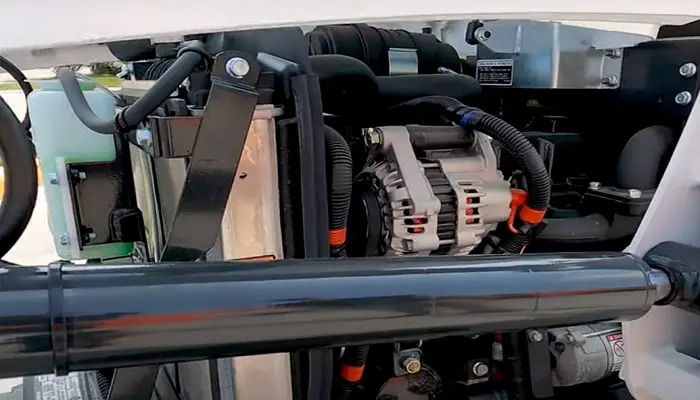

The most common problems with a Bobcat CT1025 tractor include starting troubles, bad fuel shut-off solenoids, defective tires, crash of the drive motor, and defective braking seals. Unfortunately, finding out replacement parts is also a tough job.

However, don’t get worried about seeing the list of these problems. Instead, sit tight to find solutions to these problems by yourself. Knowing the cost will help you fix your budget for the CT1025.

What Are The Common Bobcat CT1025 Problems?

Like other tractors, the Bobcat CT1025 tractor also exhibits some problems with time. These problems are common in most tractors. However, a Bobcat CT1025 shows some issues different from other tractors.

Find out the common Bobcat CT1025 problems from the list below.

- Starting problem

- Repeated crash of the drive motor

- Defective charge pumps

- Bad quality of tractor tires

- Rare spare parts

- Faulty fuel shut off solenoid

6 Easy Solutions For Bobcat CT1025 Problems

Finding a solution won’t be difficult if you’re a pro operating a Bobcat CT1025. However, things get out of hand when an amateur deals with the issues of a Bobcat CT1025.

Don’t get afraid! We’ve sorted out the definition of these problems, their solutions, and the fixing cost of most problems.

1. Clean The Fuel Filters

The Bobcat CT1025 might give you a hard time while starting if you’re using it for a long time. These signs will tell you about the starting problem in your Bobcat CT1025.

- Irregular or rough starting

- Terrible smoke release

The problem starts from the ignition chamber or lack of fuel in the CT1025. According to expert mechanics, damaged fuel systems, defective fuel coils, and jammed filters are the reason behind the starting issue.

Since your Bobcat CT1025 is facing starting problems, it’ll eventually burn extra fuel to start, increasing the smoke amount.

So, a mechanic will want to replace the damaged coils to solve the starting issue. But cleaning the jammed fuel filters also helps to dilute the situation.

A mechanic charges 60 to 350 bucks depending on the complexity of the starting problem of CT1025. A single fuel coil costs around $30 to $150.

As you can see, you’ve to pay $90 to $500 overall to fix the starting problem of your Bobcat CT1025. Regularly clean the fuel filters of your Bobcat CT1025 to avoid starting problems.

2. Install A New Drive Shaft

The repeated crashing of the drive motor occurs when you are using your Bobcat tractor for heavy work. As a result, the bearings can’t hold longer than expected.

Oil leaking and mechanical parts tend to damage because of this issue. Many times bearings slip into oil spills and harm the internal components of the tractor.

Jammed filters are a significant reason behind the repeated crash of the motor. Eventually, it damages the tractor’s engine.

Drive motor/drive shaft is a complex issue to fix in your home yard. Replacing the drive shaft is much easier than fixing it. The repair cost depends on the time needed to solve it and its reason.

Replacing the shaft costs a hefty sum of $500 to $1000. Don’t forget to pay $200 as a labor fee. Some quick fixes will solve the problem for a short period. These fixes will waste your time and money and may hamper the tractor’s health.

The fixing cost of a faulty driver motor varies depending on the expertise of the repair shop. According to some surveys, some repair shops charge $90 to more than $150 hourly to fix the frequent crashing of the motor.

3. Change The Defective Charge Pump

A charge pump, commonly known as a braking seal, lowers the chances of free fall. But a defective charge pump can’t provide enough pressure to the brakes. This issue is sometimes connected to the motor.

It’s not a surprise to fix the motor when the problem is with the breaking seal of your Bobcat tractor. As a result of this issue, the tractor tilts to one side, creating an imbalance.

Before the charge pump affects the tractor’s motor, changing it will help minimize the damage. Consult with an expert if you are facing any braking problems. Then, change it with an expert’s help.

You must pay 100 to 300 bucks to replace a defective charge pump. Some shops will charge you hourly to fix the brake seal. Plus, these shops charge extra for the additional parts.

4. Replace The Bad Tires

Tractor tires won’t last long if you drive your Bobcat CT1025 on rough surfaces like concrete and asphalt. But you’ll face the same problem with Bobcat CT1025 while driving it on your farm.

Many CT1025 tires have flat tires from the beginning. So, these tires fail to provide desired grips.

It’s best not to drive your CT1025 on rough surfaces to use the tires for a long time. Drive your Bobcat CT1025 on a farm or field. It would be best if you change the tires as soon as possible once they start losing grip.

The fixing cost depends on the price of different wheel parts—a Bobcat CT1025 wheel rim costs around $148. You’ve to pay an extra three bucks for the front wheel bolt.

A Bobcat CT1025 front tire costs $88.51, and a valve stem will cost you $7.04. So, the total sum is around 250 bucks if you want to replace every part of your CT1025 wheel. Don’t forget the additional installation cost and downtime cost.

5. Keep Extra Parts Handy

Well, you use a tractor for heavy work, which damages the parts of the Bobcat CT1025 tractor. The issue gets even worse if you’re living in a rural area.

Primarily, it’s tough to find brakes like ‘We multi disc’ brakes and infinite, 2-range hydrostatic transmissions. Plus, the general parts are only available in a tractor shop or a tractor repairing shop.

The solution is to keep extra parts available when facing braking and transmission problems.

If you don’t have enough knowledge and try to change these parts yourself, it might lead to complex engine issues. So, contact an experienced mechanic to crack the problem as soon as possible.

The fixing cost changes according to the expertise of a mechanic in this sector. Each brake disc plate costs 2 to 3 bucks. The average price ranges from $35 to $50.

You’ve to spend 40 to 50 bucks on replacing a faulty brake. Then comes the 2-range hydrostatic transmission.

Some hydrostatic transmitters will cost you $50, and some will cost around $20 to $30. So the total replacement cost comes to about 100 to 120 bucks.

6. Get New Fuel Shut-Off Solenoids

Fuel shut-off issues are scarce in a Bobcat CT1025 tractor. A faulty shut-off solenoid won’t correctly stop the fuel supply. It will only waste fuel while driving the CT1025 tractor.

You won’t hear any clicking noise while starting the engine. This is because the tractor’s battery won’t provide enough power to activate the solenoid.

Fixing a defective fuel shut-off solenoid is tricky since it is operated electromagnetically. The only solution to this issue is replacing the solenoids when the signs match the symptoms of the faulty shut-off solenoid.

You must pay the mechanic fees and bear the solenoid cost since replacing the shut-off solenoids is the only solution for this problem. A single solenoid costs between $15 to $100. The price goes up to 50 to 300 bucks if you’ve multiple defective shut-off solenoids

The mechanic fee is $60 to $100 per hour. Altogether you’ve to pay 100 to 400 bucks to replace a faulty fuel shut-off solenoid.

Frequently Asked Questions (FAQs)

While going through some forums and discussion groups, we’ve found the below question that people are seeking an answer for. You may also go through this section to learn more about bobcat ct1025?

Is Bobcat CT1025 worth the money?

Yes, the Bobcat CT1025 tractor is worth the money. This tractor will give you a smooth ride while driving on your farm or field. It’ll last longer if you take proper care of the Bobcat CT1025.

What is the maximum lifting capacity of a Bobcat CT1025?

The maximum lifting capacity of a Bobcat CT1025 is 700lbs or 318 kg. You may customize the tractor depending on your work. A farmer doesn’t have to lift more than 700lbs on his farm. So, hardly any modification of a CT1025 is required.

What is the life expectancy of a Bobcat CT1025?

The life expectancy or warranty of a Bobcat CT1025 is two years or 2000 working hours. The warranty includes different parts of the Bobcat CT1025. Some customers reported that Bobcat CT1025 lasts longer than two years if maintained regularly.

Are Bobcat CT1025 tractors affordable?

Yes, Bobcat CT1025 tractors are pretty affordable. The official price of a brand new CT1025 is $23,5000. It comes with a 25hp engine, 700lbs lifting capacity, a loader, and a bucket. During its lifespan, the CT1025 provides fantastic service.

Conclusion

As you can see, the Bobcat CT1025 has some flaws but taking proper care helps to reduce the chances of defects. The problem’s name helps to detect which part of the CT1025 is defective.

We hope the discourse has helped you to discover the common issues of CT1025 and their remedies.

Try to fix the problem when you’ve enough experience driving a Bobcat CT1025. Otherwise, please take it to an expert mechanic. Keep some extra parts in stock in case of emergency.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!