How to Fix Common Bobcat 863 Skid Steer Loader Problems?

The Bobcat 863 is a great vehicle of choice for skid steers if you want one that is both affordable and powerful. Before buying this model, you should be aware of some of the problems that you have to face with this vehicle.

The most common problems with the Bobcat 863 are fuel issues such as fuel leakage or low fuel pump pressure, hydraulic issues such as clogged hydraulic filter or low hydraulic oil as well as problems with electrical connections.

In this article, we go through 7 of the most common problems that users of Bobcat 863 face with the skid steer model.

What Are The Common Bobcat 863 Problems?

The problems that users face with the Bobcat 863 can be broadly classified into electrical problems, steering/hydraulic issues, ergonomic problems etc.

If you look more specific, the following are some of the most common issues that users mostly face with the Bobcat 863 skid steer loader.

- Fuel leakage/low fuel pump pressure

- Hydraulic oil filter

- Low Hydraulic oil level

- Engine oil pressure light comes on

- Flashing Red light

- Leaking hydraulic hose

- Problem with Seat belt

7 Easy Solutions For Bobcat 863 Problems

As the problems mostly originate from the fuel system, hydraulic system and the electrical system, you need to make regular inspection of each of these compartments.

1. Fuel Leakage/Low Fuel Pump Pressure: Check For Leaks And Replace Fuel Line If Clogged

Fuel leakage or low fuel pump pressure often results in air getting stuck in the fuel system which causes engine performance to deteriorate or even worse, an engine failure.

To combat this problem, you need to check for leakage or clogs. Follow these steps for that.

- Turn off the ignition key.

- Take off the filler cap and then turn on the engine. Put the filler cap back on.

- Once the engine warms up to operating temperature, turn off the engine and take off the filler cap. If the engine is still operational and running after a few minutes, then there is enough air in the fuel pump. Otherwise, you might have a clog in the fuel line.

- Check if any of the fuel lines are clogged. If you find it, get it replaced immediately.

The price range for getting a new fuel line is wide. At the cheapest, you can get it for as low as 12$ but at its highest, it can exceed $400.

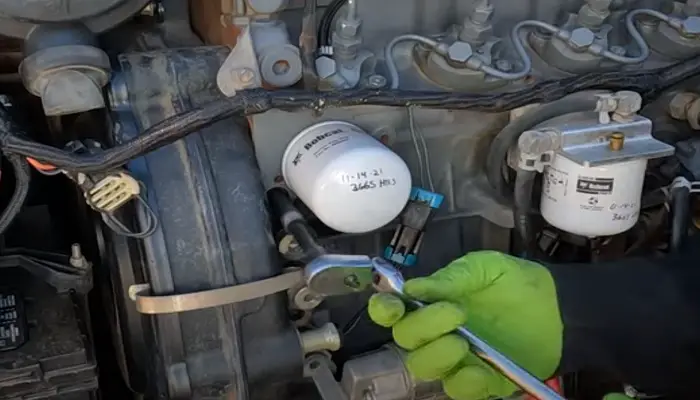

2. Clogged Hydraulic Oil Filter: Replace Hydraulic Oil Filter

The job of the hydraulic filter is to reduce the amount of dirt entering hydraulic fluid and to prevent contamination.

But once the dirt-holding capacity is depleted, the filter becomes as good as useless. The only solution then is to change it by following these steps.

- Place the Bobcat 863 on level ground and hold the parking brake.

- Remove the cap from the hydraulic oil reservoir.

- Start the engine and keep it on for at least 3 minutes.

- Place a container under the oil reservoir to catch the leaking oil when emptying.

- Locate the drain plug on the hydraulic oil reservoir and take it off.

- Now drain out all of the oil within the reservoir.

- Close the drain plug.

- Locate the hydraulic oil filter and unbolt it. Take off the cap.

- Lubricate the ‘o’ rings of the new filter and then put the cap from the old filter on it.

- Bolt the new filter in the designated location.

The price for a new hydraulic filter ranges from $10 to $60.

3. Low Hydraulic Oil Level: Fill The Reservoir With Hydraulic Oil

When your hydraulic oil is low, you will notice symptoms such as reduced power on the vehicle as well, reduced vehicle speed as well as an increased amount of engine noise.

To refill the hydraulic oil reservoir, follow these steps.

- Turn on the engine and engage the parking brake. Let the engine warm up to operating temperature.

- Turn off all of the secondary hydraulic functions. Then have the loaders raised to its furthest height and then lock it in place.

- Open the rear access door on the Bobcat 863.

- Look for the sight glass windows on either side of the front axle of the vehicle. Then proceed to clean any dirt or dust around it with a damp rag.

- Take an eye dropper and use it to pour in hydraulic fluid through the sight glass windows until it is halfway full.

On average, you will have to spend between $30 to $40 per gallon of hydraulic oil .

4. Engine Oil Pressure Light Comes On: Replace Engine Oil Pump

If the engine oil pressure light turns on, it is a sign that the engine oil pressure is low. This may be due to low level of engine oil which causes the reduced pressure.

When the engine oil pressure light turns on, follow these steps to fix the problem.

- Check for leaks around the fill tube for the engine oil. To locate the fill tube, search at the top of the engine under the nose of the operator’s seat.

- Inspect the tube to check if there are any holes or cracks.

- Also check for any loose connections on the tube. If found, tighten them.

- If no signs of leakage are found, then turn on the engine.

- As the engine warms, inspect the gauge oil pressure. Check if the pressure is at least 4 psi. If not, then the oil pump has a problem.

- Take out the dipstick from the reservoir and inspect the ‘O’ ring to see whether it is properly sealed.

- If all of the steps are done and no problem has been done, then you have to replace the engine oil pump.

Replacing the engine oil pump will cost you between $80 and $150.

5. Flashing Red Light: Remove The Corrosion Using Sandpaper Or Steel Wool

If you notice the red light on the Bobcat 863 flashing, then this indicates some wiring issue in the engine compartment.

To deal with this problem, do the following.

- Gain access to the engine

Open the Bobcat’s hood to access the engine compartment. Look for the covers on the sides of the engine compartment. Take a screwdriver and use it to unbolt all the covers. Once unbolted, take them off.

- Disconnect the battery connections

Locate the battery wire connections. You will find the wires under a plastic cover. Take it off and then proceed to decouple each of the wires one by one. Make sure to start with the single green wire and then proceed to the black ones. Use pliers for complete disconnection.

- Diagnose and reduce corrossions

Inspect each wire individually to identify any signs of damage or corrosion. Use steel wool or sandpaper to remove any bit of damage or corrosion.

The red light situation can be fixed with a DIY solution, so no extra cost is needed for this.

6. Leaking Hydraulic Hose: Replace The Hydraulic Hose

The most obvious way to diagnose a leaking hydraulic hose is the presence of water puddles underneath the Bobcat 863 vehicle. Other symptoms include poor performance and low levels of hydraulic fluid.

To diagnose and fix the hydraulic hose issues, do the following.

- Acces the hydraulic reservoir

To locate the hoses, you need to access the hydraulic reservoir first. You will find a hose going from either side of the reservoir to a big metallic tube that goes down to the vehicle’s underside.

The hoses are tightly held in place using clamps. Unclamp and pull out the hoses.

- Clean the hose housing

Before pulling out the hoses, make sure to clean the grease and oil from the place on which they were placed. This ensures easier seating of the new hoses and prevention of any possible leaks.

- Get an appropriate replacement

Try to replace the old hoses with ones of identical size and bore. If not, then get one that is slightly larger since hoses tend to shrink in size due to usage, ensuring eventual fit.

Bobcat hydraulic hoses cost between $60 and $140.

7. Problem With Seat Belt: Rearrange The Seat Belt

A common problem with the Bobcat 863 is that often the seat belt is not working. This indicates some mismanagement of the seat belt system within the skid steer.

To fix this issue, do the following.

- Rearrange lap belt

If the seat belt you have is only a lap belt, then you will be able to unfasten it at the seat’s back to a hook that lies on the machine frame. The catch on the seatbelt should not rotate beyond 360 degree direction.

Lift up the catch and rotate it in a counter clockwise direction. You will find that this detaches the catch and thus open for removal.

- Rearrange shoulder belt

In case the only seat belt is a shoulder belt, you should first check that you have nothing trapped in the space between the base of the seat and its’ back

- Check ana apply oil on the upper part of the back seat

Inspect to see if the clamp on the upper part of the seat’s back is free to move up and down. There might be dirt, dust or mud stuck between the housing and the clamp. Use some oil lubrication to free the area. .

The seat belt only requires a simple DIY fix, so no cost is associated with this problem.

FAQs On Bobcat 863 Problems

As a regular user of the Bobcat 863, we know that you have a lot of questions that keep popping up from time to time. Below are some of the most questions that readers ask on problems associated with the Bobcat 863.

What Are The Common Electrical Issues With The Bobcat 863 And How To Deal With Them?

The most common electrical issues are flashing red lights or engine oil pressure lights coming on. In the first case, you will need to get rid of the corrosion using sandpaper or wool.

In the latter case, the solution is to get a new engine oil pump.

How To Deal With Seat Belt Problems On The Bobcat 863?

In the case of a lap belt, the solution is to rotate the belt counterclockwise and the catch will be released. If it is a shoulder belt, then you need to clean any dirt or dust between the base and back of the seat.

Why Am I Having Steering Issues On My Bobcat 863?

Steering issues come from faults with the hydraulic system. Either the hydraulic filter is clogged or you have a low amount of hydraulic fluid in the reservoir.

What To Do When I Have Fuel Problems On My Bobcat 863?

Check for any leaks within the fuel system after turning the engine on and keeping it at idle for a few minutes. If there are no leaks, then check for clogs. If a clog is present, then you need to get the fuel line replaced.

Conclusion

As the old saying goes, “Prevention is better than cure”. So if you want to avoid any of the problems that we discussed here, then make sure to maintain regular maintenance of the Bobcat 863.

But despite all prevention efforts, things will inevitably go wrong. Whether the problem is fuel related or a hydraulic issue, always make sure to dispose of the excess fluids in an environmentally safe approach. Check the local regulations on how to do that.

Also be mindful of the appropriate precautions when working with batteries and the vehicle wires. Wear gloves and goggles and keep the battery disconnected before operating on the wires.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!