How to Fix Common Bobcat T66 Track Loader Problems?

Bobcat T66 is one of the finest track loaders available in the market. With many exclusive features and benefits, it has become quite popular among users. That said, still many users face several issues while using this track loader.

Some of the common problems with Bobcat T66 include it doesn’t move forward or back, non-working operator loader button, non-operational lift and tilt function, issues with hydraulic system, issues with the engine, etc.

Whatever problem you may face with this model, the good news is there is a solution for every T66 problem. All you have to do is apply the right troubleshooting techniques. In this article, I will tell you about how to fix some common Bobcat T66 problems.

What Are The Common Bobcat T66 Problems?

As we mentioned above Bobcat T66 is a great track loader. However, if you know the proper solutions to a problem, you will not get stuck in the middle of the road.

Below we will mention some of the common Bobcat T66 problems mentioned below for you.

- Engine fails to start or operate properly

- Poor loader operation

- Non-responding Joystick controls

- Non-responding steering

- Inability to move forward or back

- Non-working operate loader button

- Non-operational lift and tilt function

7 Easy Solutions For Bobcat T66 Problems

Whenever you face any issue with your Bobcat T66, don’t panic. Because every problem of this model can be solved with proper troubleshooting techniques. Explore solutions for some of the common Bobcat T66 problems below.

1. Engine Fails to Start or Operates Properly: Identify the Cause and Take the Right Action

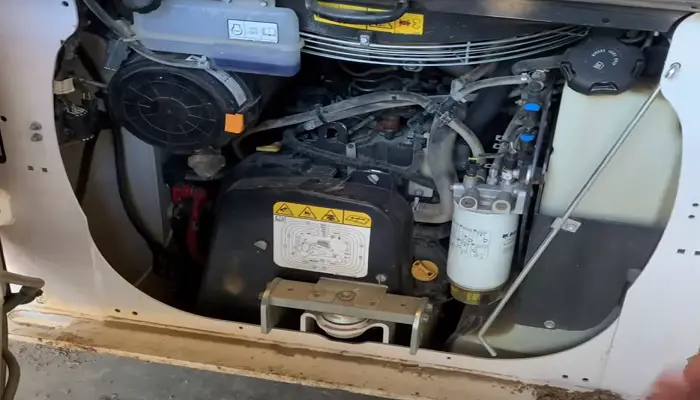

There can be several causes for this problem of Bobcat T66. First of all, you must thoroughly check the entire fuel system. There are mainly three elements in the fuel system- tank, fuel lines, and fuel filters.

If you work with Bobcat T66 in a dusty nature, you should replace your fuel filter regularly.

It can cost you $30-$40 to replace it. Fuel should be able to flow without any restriction from the tank to the fuel injector.

If there is any clogging in the injector, you must remove that. You should also check the glow-plug lead wires so that their connections are snug.

If the connections are not snug, the engine and the combustion chambers will not warm properly in the cold. Besides, you also need to ensure that the throttle cable is properly secured to the body.

2. Poor Loader Operation: Find out the Cause and Take Proper Action

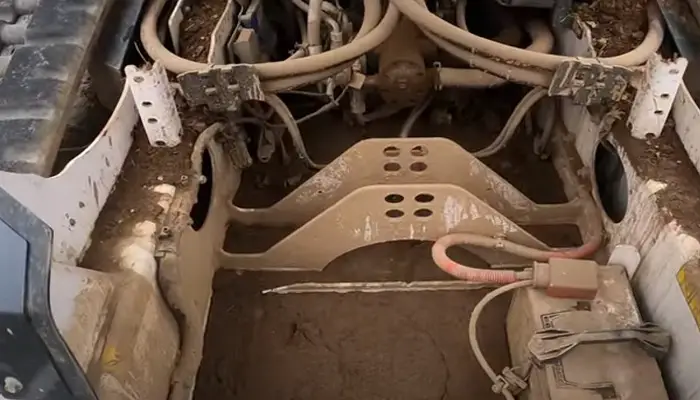

This issue is disappointing. It mainly happens due to issues in hydraulics of Bobcat T66. If there is excess fluid in the hydraulic reservoir, this issue may happen.

So, you must check the reservoir and make sure that there is the recommended level of fluid. Then, you must check the fuel filter. If there is any clogging, fluid won’t feel free and the loader will operate poorly.

Furthermore, if the hydraulic pump is not operating perfectly, the Bobcat T66 will also operate very poorly. Check the hydraulic pump on the front side of the engine. Make sure to correct everything you find if there are any problems.

If there is any leak or fitting is poor in any hydraulic lines fittings, the loader will operate poorly. So, check all fittings to find any leakage.

Furthermore, the control valves should be able to open or close completely. That’s why you should also inspect all seals and fittings there carefully.

3. Non-Responding Joystick Controls: Secure all Connections Properly

If you have joystick controls with your Bobcat T66, it should be operating smoothly.

But, many users argued that their joystick control doesn’t work properly. You could experience this problem if all of the connections are not completely secured.

First of all, you need to check the joystick control, and circuit board. You will find the board on the armrest of your joystick control. You must address any problems if there are any.

However, if the problem is not fixed yet, you must inspect the connecting wires from the joystick to the hydraulic pump and actuators.

The connections there should be secured properly. In a nutshell, when you face any issue with your joystick control panel in Bobcat T66, you should inspect all connections and fix them if you find issues.

4. Non-Responding Steering: Secure all Connections, Inspect and Fix connections in the Safety Switches

If the steering of your Bobcat T66 is not responding properly, you must check whether all the connections are properly secured or not.

Because in most cases, the reason for this issue is loose connections. Inspect every wired connection and make sure that they are properly secured.

Another cause for this problem can malfunction in the control system. Whether you talk about the driver’s seat or other panels, you will find several safety switches.

These safety switches could malfunction, which would affect the machine’s steering system.

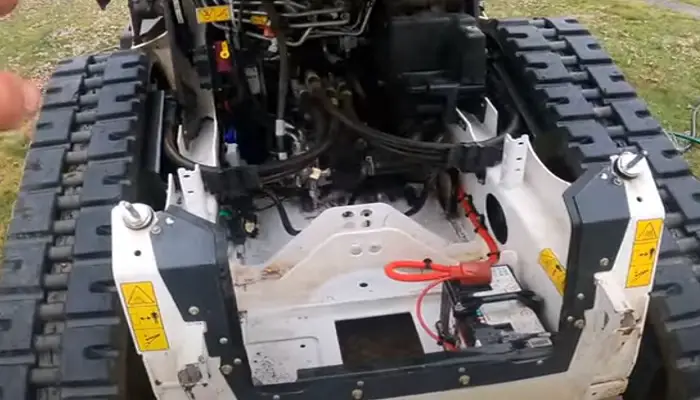

Inspect the switches and confirm that there are good connections. Besides, if the battery of Bobcat T66 is draining excessively, there can also be a bad circuit. In that case, you should prevent the excessive draining of the battery.

5. Inability to Move Forward or back: Adjust the System Voltage, Replace the Solenoid Circuit

Another issue that Bobcat T66 users usually face is they can’t move the machine forward or back.

This issue is quite frustrating and undoubtedly your overall productivity and task schedule will be affected due to this issue. Typically, this problem can happen due to the following reasons.

Firstly, there may be too low or high system voltage. So, you should inspect the voltage thoroughly. If it is too low or high, adjust the system voltage.

You may need to replace a fuse to fix the problem. This issue can also happen when the solenoid circuit is open.

Also, if it is shorted to battery voltage or ground, you may not be able to move the loader forward or back.

However, it will be a wise decision to replace the solenoid circuit if it is damaged. The cost of the circuit may vary.

But, you should be able to get a new one for $15-$400. If you are done with the replacement, the loader will start to move forward or back.

6. Non-Working Operate Loader Button: Fix Loose or Bad connections

Another common problem with Bobcat T66 is the non-working operate loader button. It is a frustrating issue.

Because if the operate loader button doesn’t work, you will be stuck there. A couple of causes play important roles in creating this problem.

For example, if there is any loose or bad connection in wiring and fuses, you may face this problem. To solve the issue, you should inspect the relay and fuses located in the area where you place your foot and in the back panel.

To check the connections thoroughly, you will need to remove the connections. When you fix the loose or bad connections, the operate loader button will work again.

7. Non-Operational Lift and Tilt Function: Refill the Fuel Tank, Fix bad solenoid

One of the common problems users face in Bobcat T66 is the non-operational lift and tilt function.

To be honest, when this problem happens, you are stuck at your work until the problem is solved. There can be a couple of reasons for this issue.

First of all, you need to check the fuel level in the tank. Because a low level of fuel will create this issue.

In that case, you will need to refill the tank with fresh fuel. Besides, if there is a bad solenoid, the lift and tilt problem can also happen.

When the valve output circuit is in the open position, you may face this issue as well.

So, fix the circuit of valve output to solve the problem. If the circuit is damaged, go for a replacement which may cost you around $60-$70.

Frequently Asked Questions (FAQs)

Should you have further questions, you can explore our FAQ section below to get the answer of some commonly asked questions.

What engine is in Bobcat T66?

Bobcat T66 comes with a very powerful engine. You will get a tier 4 engine commission 74hp liquid and diesel engine in this track loader. No wonder, it will be able to give you a better user experience.

How much can a Bobcat T66 lift?

The horsepower of the Bobcat T66 is 74. With this excellent HP, it will offer you a great lifting capacity of 2450 lbs. It comes with very powerful hydraulics and breakout forces. As a result, you can enjoy increased lifting capabilities from it.

What size is Bobcat T66?

Bobcat T66 has excellent size to give you a better user experience. The length of this machine with a standard bucket is 134.9 inches. The length of the track on the ground is 54.3 inches. Besides, the length without attachment is 107 inches.

Can there be any issue with the lift and tilt function of the Bobcat T66?

Yes, there can be issues with the lift and tilt function of Bobcat T66. Typically, this issue occurs when a fuel tank lacks adequate fuel. Besides, a bad solenoid can also be the reason for this issue.

Conclusion

Bobcat T66 is an excellent track loader with a powerful engine and decent lifting capacity. Many users expressed their positive opinion about this product. However, they also face some issues when using this track loader.

If you know the solutions to a problem, you don’t need to fear it. Each issue of Bobcat T66 can be solved with proper troubleshooting techniques.

In this article, we discussed how to fix common Bobcat T66 problems. We hope it was helpful and that you will be able to fix any issue with this model in the future. Just follow the instructions properly and get the job done.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!