How to Fix Common Bobcat E42 Mini Excavator Problems?

Mini excavators are heavy-duty machines designed to withstand serious external damage and stay by your side for a lifetime. Unlike regular excavators, these excavators are more nimble and fast-paced. Among the best mini excavators models from Bobcat, E42 stands out for its power and durability.

However, Bobcat E42 also has some limitations which turn into problems over time. It suffers from various problems like hydraulic leaks, bearing failure, high pressure, etc. Not only do these problems decrease the lifespan of the vehicle but also decrease efficiency significantly.

Now fixing these problems is a must and since they appear commonly in all the Bobcat E42 mini excavators, identifying and resolving them is of utmost importance. Stay with us throughout the article to learn about the problems and solutions.

What Are The Common Bobcat E42 Problems

To better understand the problems of your mini excavator, you must know a few basics of this vehicle. Quite surprisingly, the engine has an output of 42.7hp and provides a torque of 2200rpm.

The problems, however, occur from different parts of the excavator which are indirectly related to the massive power output of this vehicle. The common problems you’ll face because of this power output are as follows:

- Hydraulic Leaks

- Bearing Failure

- Case Drain Problem

- Gear Oil Leakage

- Frequent Overheating

5 Solutions For Bobcat E42 Problems

Mini excavators have a few problems that require immediate replacement for fixing but most of them can be fixed after a few days.

Here you’ll get to know about the solutions for the most common problems that have occurred to 90% of Bobcat E42 mini excavators.

1. Hydraulic Leaks: Identify And Replace

This is a tough problem and requires intricate knowledge about your bobcat E42 in case you want to fix it manually. The problem occurs from the crown seals and jams the hydraulics until leaks begin to occur in the system.

In addition to that, the mini excavator starts to lose efficiency because of the fluid leaking instead of passing through the hydraulics system.

- Check for any flat spots where the crown seal is located

- The spot is usually made of silicone or plastic and you need to rub it.

- Inspect the ground beneath your mini excavator for puddles of fluid.

- As soon as you find the leak beside the crown seal, repair the swivel joint using plastic nylon spacers

- Check for any other leaks after replacing the damaged hydraulic part.

This whole process is a bit complicated since you have to check and repair under your mini excavator.

It’s recommended that you take your construction equipment to an expert. Note that it’ll cost you about $500 to $2500 depending on the extent of the leak.

2. Bearing Failure: Proper Maintenance Necessary

Ball bearings failure is a problem related to the main bearings of your Bobcat E42. Simply put, the main bearing requires regular maintenance and the lack of this maintenance will cause this problem.

- The proper way to identify this problem is if your mini excavator is having trouble moving any of its parts properly.

- Turn off the engine of your mini excavator for an hour or two.

- Check your mini excavator’s main seal for the leak of bearing lubricant.

- If you spot even the slightest leak of lubricant, you need to fill the bearing immediately.

- Replace the final drive if the extent of damage is beyond repair.

This is a very serious issue and can destroy your mini excavator before you even realize it through excessive stress. The Dx340 Slewing Bearing Ring will cost you about $1700 and an expert repair will cost you about $3000.

3. Case Drain Problem: Various Fixes And Adjustments

Sometimes your Bobcat E42 will begin to heat up uncontrollably. It’s due to a variety of problems including hot weather.

The easiest way to identify this problem is to notice white smoke emitting from the engine lid. Below you’ll find solution hints for different scenarios.

- Check the case drain filter for any form of clogging and give it a thorough clean.

- See if the cover plate is in place and sealed properly. If it’s broken, buy a new one and replace it.

- Inspect if the gear oil has mixed with the hydraulic oil. If this happens, you’ll need to empty the containers and clean them. Don’t use the mixed oil again, throw it away.

- Don’t keep your Bobcat E42 under the sun for days on end.

All in all, this problem can be fixed by yourself or hire an expert. To buy a cover plate for bobcat E42, you’ll need about $270. Meanwhile, the whole check-up and repair by hiring an expert will cost you over $750.

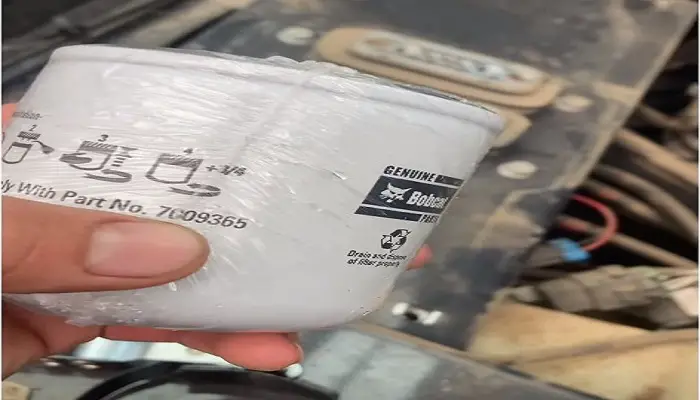

4. Gear Oil Leakage: Repair And Replenish Oil

Bobcat E42 has an oil capacity of 6.3 liters and a coolant capacity of 8 liters. Mini excavators have oil leaks because of external damage to the oil filters.

The oil needs to be changed every few months or this problem becomes frequent. You can easily identify the leakage by checking how fast your vehicle consumes oil. Here’s how you can fix them right away.

- Check the oil meter on your mini excavator and fill it up a little if it’s empty.

- Patiently inspect the lower part of your vehicle and try to identify the leakage.

- If there are more than 3 leaks, you need to replace the whole oil filter system.

- However, if there are one or two leaks, repair them with industry-grade tape.

- Finally, empty the whole oil container and fill it with premium quality oil.

It will need some time and expertise to complete the task. There is always the option of calling an expert.

The overall cost for oil leakage fixes will cost you $300 including the expert fee and about $1100 if you need to replace the whole oil system.

5. Frequent Overheating: Engine Inspection And Repair

The E42 model uses its very own Bobcat D24 diesel engine which has some issues with overheating from time to time. Honestly, the engine is superior in terms of power and can hold up to 9972lbs.

However, it has problems keeping the engine cool after the engine gets a bit old. You need to inspect the various parts of the engine to identify the problem given below:

- Check if the gears are oiled and clean the oil filter if the oil flow is not spontaneous.

- Inspect the ignition coil for damages and replace it if you find any.

- Open the cooling system and check for any jammed particles in the tube.

- Remember to check and fill the coolant if it’s empty or close to empty.

- Inspect if the thermostat is working properly and replace it accordingly.

In case these fixes are unfamiliar to you, hiring an expert is the next best idea. The cost of a full engine check-up will be $1300 without the addition of replacing any parts such as the thermostat or ignition coil.

Frequently Asked Questions (FAQs)

Bobcat E42 mini excavator is widely used for professional construction all over the world. For this reason, some questions are frequently seen to be appearing from users of this model. Here is the short solution of those queries.

Why is the extendable arm of my Bobcat E42 stuck?

This problem occurs because of one or both reasons. One being the hydraulics problem and the other being the bearing problem. Check both, spot the problem, and fix your mini excavator’s extendable arm.

Is the Bobcat E42 a fire hazard in case of white smoke emissions?

No, the engine is the only part of the mini excavator that uses diesel. Even if the engine catches fire, it won’t spread to the driver’s seat.

Why is the final drive of my Bobcat E42 not working?

A common scene for mini excavators in large is the final drive oil contamination. Simply change the oil quality and let it burn for a while to make the final drive work again.

What is the reason for the constant wheezing sound of Bobcat E42?

The constant wheezing sound originates as a symptom of bearing failure. You must stop the E42 immediately and apply bearing lubricant to the affected region to stop this sound.

Why has the oil intake suddenly increased in my Bobcat E42 model?

Oil leakage is the most likely cause of the abrupt rise in oil use.Check beneath your E42 for spots of oil and repair the oil connection. Remember to use industrial tape for a temporary repair.

Conclusion

Bobcat E42 is a great addition to the mini excavator market for its aggressive power and long-lasting durability. The lifespan of the E42 is usually 10,000 hours but with proper maintenance, you can keep using this construction equipment your whole life.

Although you’re sure to encounter some common problems from time to time, you’ll be able to deal with them easily. Now that you know how to identify the problems you might face while using Bobcat E42, you can rest assured that you have the upper hand when it comes to problems.

Remember to take the help of an expert and replace the damaged parts whenever you spot them. Take care of your construction equipment so that it can take care of you. Thank you for your patience!

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!