6 Reasons Why Ventrac 4500 Won’t Start and Their Solutions

If you are into driving tractors, Ventrac will definitely satisfy you. While it does have a unique line-up of features, people have still complained about their unit not starting. So why exactly does the Ventrac 4500 not start?

Well, most often, if you have a cranky engine and your Ventrac refuses to start, the fault might lie with the valves. Sediments of rock and dried-up oil are the main culprits behind closing off the valves. In addition, electrical problems can also cause your Ventrac 4500 not to activate.

If you are facing these types of problems with your Ventrac tractor, you might also be looking for solutions. In this article, we will be covering why exactly Ventrac 4500 won’t start, along with how to resolve the issue.

What Causes Ventrac 4500 Won’t Start?

If your Ventrac 4500 won’t start, there might be a lot of pending work to be done. If you are going to get out of this pinch, you should first identify what exactly can cause your tractor to stop working.

Below, we have compiled some of the most common reasons attributed to the deactivation of Ventrac 4500.

- Vent Blockages

- Electrical Issues

- Faulty component

- Battery Problems

- Bad outdoor temperatures

- Wrong or stale oil

6 Solutions For Ventrac 4500 Won’t Start

Depending on what problem exactly is causing activation issues on your tractor, you might need to take different approaches. We have compiled six different solutions that you can try out.

1. Vent Blockages: Clear Out The Blockages

Vent blockages are one of the most common reasons why your Ventrac might not start. This is usually caused by the accumulation of rock sediments and dried oil that blocks the vents.

Once the vents are blocked, no oil can be processed in your engine. This results in a cranky, sometimes overheating, engine. If left alone, this can even cause correlated components to burn out from the heat.

To resolve the issue, all you need to do is clear out the vents. You can do this by making use of a cleaning agent and wiping. Once cleaned up, the vents should be working as usual.

Since you can resolve the problem on your own with the products you already have on your head, no labor cost is involved. If you need to buy a cleaning cloth and an agent, the total might be around 10 USD.

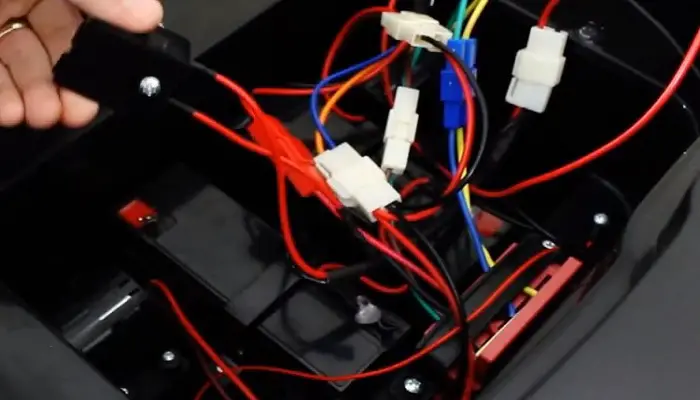

2. Electricity Problems: Replace Fuses And Tape Up Wires

If your tractor is facing electricity problems, there is a high chance that the fuses might have blown. With the fuses blown out, no electricity will pass through the circuit.

You can make use of a voltmeter to diagnose whether there are broken fuses or not. With no electricity passing through the wires, the voltmeter will not show any voltage reading.

To resolve this problem, you will be required to replace the old fuses with new ones. Since fuses are typically not repairable, buying new ones is the only available option.

You might also find these broken fuses being accompanied by torn wires. If that is the case for you, you can use a tape that is safe for electric usage to patch up the wires.

The total cost involved in this problem and its solution is not much. At least expect to spend around 10 USD. However, if you are going to avail a mechanic, you might need to pay an extra 50 to 100 USD. This is usually charged on an hourly basis.

3. Faulty Components: Tighten The connectors and replace them if required

Faulty components usually involve smaller items like sensors, gears, gauges, etc, that can be subjected to damage caused by time. Even if they aren’t damaged, they can also end up loosening up.

To patch up issues related to your components, you should run regular maintenance at a certain interval. This involves tightening the connectors and replacing the sensors.

To fix disconnected or loose components like connectors and pins, you must have power tools like a screwdriver and spanner in your hand. When it comes to sensors, they might not always be fixable. In that case, buying and replacing with a new one might be the only choice.

Since there are no external products used in this solution, no costs will be spent. However, if you need to replace sensors, expect to pay around 5 to 30 USD.

4. Battery Problems: Reconnect The Battery

Sometimes your battery might not be able to provide the correct amount of energy needed to start the tractor. This can be caused by corrupted run-time data or even a traction control prevention mechanism.

To fix this problem, the quickest solution is to reset the entire system. Before going on the resetting, make sure to check whether the voltage of the battery is fine or not.

If no readings are shown, you might need to replace the entire battery. Once you have done the reset, you can choose to reconnect the battery.

The price of a tractor battery is typically about 70 to 300 USD. However, this is only applicable in the case where you will need to replace the entire battery with a new one.

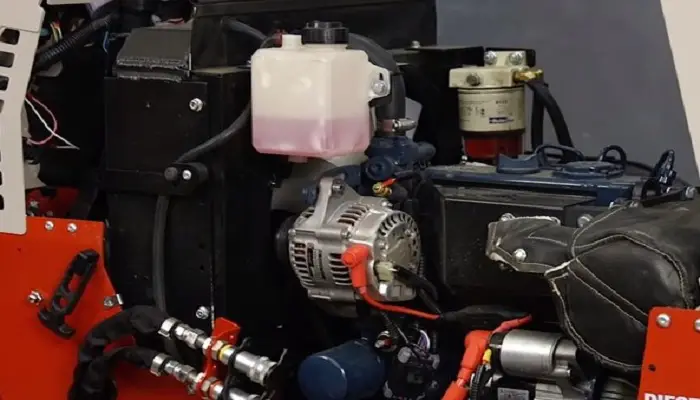

5. Bad Outdoor Temperatures: Heat Up The Engine

Problems caused by bad outdoor temperatures can range from the engine oil losing viscosity to the engine freezing up. In addition, your tires can also contract or dilate depending on the climatic conditions.

While not all of these issues can be solved on your own, If you are having tire issues, we suggest you change up to a new one. If certain components or pipes around the engine freeze, you could use rock salts to unfreeze them.

In addition, you will also need to take certain precautions if you intend to avoid engine problems. We advise you to heat up the engine every morning before using the tractor.

There are no external costs involved in this solution. However, if you are going to change tires, you will be required to pay an average of 1500 to 2000 USD.

6. Wrong or stale oil: Change the Oil supply.

Oftentimes, you will find out that even though there is no issue with the physical state of your tractor, the Ventrac still won’t start. The culprit of these types of problems typically tends to be the oil.

To be more precise, it is usually due to the wrong oil type you might have used. In addition, if your oil has gone stale or its density has been changed over time, the engine can still end up rejecting this.

There are no fixes for this problem. All you need to do is remove the old batch of oil and refill it with the right oil type. Make sure that the oil you are using is compatible with the engine of your Ventrac.

There are no components or cost of parts involved in this solution. However, you will need to be careful with this type of problem since regular exposure to the wrong type of oil can be bad for your engine.

FAQs About Ventrac 4500 Won’t Start

If you are at the end of this article, there might be several questions that you might want to ask. In section, we will try our best to give answers to a few of these questions.

Why Does My Tractor Click When I Start It?

The real reason why your tractor might click while starting might be due to a malfunctioning or near-malfunctioning solenoid. The solenoid connects the battery to the starter motor and produces electromagnetism to get the motor running. It clicks loudly if it can’t function properly.

How Do I Know If My Fuel Pump Is Bad?

You can know if your fuel pump is bad by checking on the engine of your tractor. If the engine runs poorly or produces sound, this is a sign that the fuel pump has gone. A decreased fuel efficiency can also be a sign.

Where Is The Starter Relay Fuse Of Your Ventrac Located?

If you search under the hood of your tractor, you should be able to find a black box. The starter relay fuse is located there. If the fuse is removed, the starting motor will not work anymore.

How Do You Check If The Starter Relay Of Your Tractor Is Working?

You can run a resistance test on your relay circuits to determine whether they are working. Connect a multimeter; if the reading is more than 5 Ohms, you will need to replace the replay.

Conclusion

Ground leveling depends heavily on tractors, and Ventrac 4500 is the best in the industry. However, since they are heavy-use commercial-grade tractors, they can break down quite easily.

Well, if you have read through this guide, hopefully, we will be able to help you out in case your unit stops working as well. While you can patch up the problems independently, we understand that not everyone might be up to the mark.

In that case, you are more than welcome to hire a professional to help you out with the fix. After all, the professional mechanics know how to get things fixed in the best way.

Related Posts:

- How to Fix Kubota Tractor Won’t Start Safety Switch?

- 5 Reasons Why Your Tractor PTO Won’t Engage

- Reason Your Tractor Won’t Turn Over and Solutions

- LS Tractor Won’t Start (Causes and Fixes)

- Most Common Problems with John Deere 3046R and Fixes

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!