How to Fix Common Bobcat T190 Track Loader Problems?

Bobcat is a renowned name in the world of heavy construction and garden machines. The Bobcat T190 is no exception; it is built tough and provides top-notch performance when compared to its rivals. However, just like other machines, this compact Track Loader also suffers from some problems.

Even though Bobcat T190 is a beast in compact track loaders, it still suffers from problems like a damaged case drain filter, leakage in the final drive, leaking hydraulic pump, and the engine suddenly dying. There are few other minor issues. But, the ones mentioned above are the most common.

Thus, if you are a Bobcat T190 user searching for Bobcat T190 problems, then you should read this article to know all these problems and their solutions.

What Are the Common Bobcat T190 Problems?

The Bobcat T190 is one of the most reliable machines out there on the market. However, from our experience and research, we found out the problems that can bother the users.

- Damaged Case drain filter

- Leakage in final drive

- Leaking Hydraulic pump

- Engine dying

- Engine Overheating

- Breakdown of final drive due to gear oil

6 Easy Solutions for Bobcat T190 Problems

The Bobcat T190 problems are solvable, but you must probably know how to solve them. Thus, below, we will discuss all the solutions to common problems; this track loader can suffer from.

1. Replace the Case Drain Filter

The final drive becomes under stress if the case drain filter becomes blocked. Without somewhere to go, it begins to cause issues like blown seals. In the Bobcat T190, clogged case drain filters are a fairly typical problem.

If the case drain filter gets clogged, you should replace it asap. Follow the instructions below to learn how to change the filter properly.

- Step 1: Locate the case drain filter

The first step is to find the location of the case drain filter. It is located in the final drive. The case drain filter is situated on the outlet pipe from the final drives to the fuel tank.

- Step 2: Removing the filter

The filter will look like a small aluminum cylinder. To prevent hydraulic fluid loss, disconnect the filter from the drain lines and make sure to block the drain pipes.

- Step 3: Dissemble the filter

Just loosen the hex screw to gain entry to the filter media. It has two springs keeping the filter element in position and a curved sintered-bronze filter component.

- Step 4: Replace the filter

Replace the filter if it is no more bronze in color. The price of a new case drain filter ranges from $15.5 to $20. The filter can simply be cleaned and reinstalled into the cylinder, though, if the damage is not severe.

- Step 5: Putting back everything

Once you are done setting up the new case drain filter, screw back the hex nut and put the cylinder back in the same place where you have opened it from.

2. Change the Broken Seals

You have a leak if oil is visible on the exterior rather than the interior of your final drive. Even a small leak on the final drive can be dangerous since it might eventually slowly damage the entire final drive. Thus, if you notice leaks, you will need to replace the broken seals.

A good set of final drive oil seals can cost between $25-$40. Please read below to learn how you can change them easily.

- Step 1: Open the final drive

The best way to replace the seals is by removing the final drive from your Bobcat T190. It is not advised to try changing the seals in place since the replacement seals’ spring tension will prevent you from bringing the two sides of the final drive case apart.

- Step 2: Remove the covering

You must take off the gear sets and final drive covering in order to disconnect the oil seal. Once it’s out, you’ll see a nut; take that out as well.

- Step 3: Remove the old seals

Use a pry tool to remove the old seals after the case’s two parts have been split. The dirt that accumulates and compacts all around the O-ring must then be removed. Remember that it is important to clean the surface very well to ensure the new seals do not get contaminated.

- Step 4: Insert new seals

You don’t want to press the new seal when installing it completely. Ensure the O-ring is snugly seated inside the tapering housing’s mouth so that it won’t come off. The seal won’t fit properly in the case until both halves are drawn back again.

When you are done installing the new seals, put back everything together and insert your final drive back into your track loader.

3. Replace or Repair the Hydraulic Pump

If you notice oil coming out in the exterior of the hydraulic pump, then it can be due to many reasons. Most hydraulic leaks are caused by temperature issues, seal failures, pressure issues, and cracks in the pump itself. Down below, we will discuss probable solutions for all the causes.

- Step 1: Replace the seals

All of the joints, seals, and connections need to be examined. Most leaking fittings and couplings may be repaired by simply tightening them, but you might need to replace hoses and seals that are broken.

- Step 2: Fix Temperature issues

Check the fuel for pollution and the filters for any form of clogs if your hydraulic pump overheats. If you see any clogs, properly clean them.

Additionally, regularly check the reservoir’s fluid level in your system. To assist, this reservoir does its crucial job of keeping your pump cool. Add fresh fluid as needed.

- Step 3: Replace the pump

Now, if you notice any cracks or breakages in the pump itself, you will need to replace it, and it will cost anywhere from $400-$700.

4. Check the Filter and Fuel Injection System

If you notice that the engine of your Bobcat T190 starts and then suddenly shuts off, this means there can be problems with the filters and fuel injection system. We will need to check each component separately to find out the exact Source of the problem.

A. Clogged filters

Clogged fuel and air filters are the main reasons your engine suddenly dies. Open your Bobcat T190 and check the filters for any type of blockage due to dust and debris.

- Air filters

Air filters allow proper airflow inside the engine for its perfect running and performance. So, when this gets blocked, the airflow is restricted. It is possible to clean them, but the better option is to replace them, as replacement air filters are available for around $35.5-$55.0.

- Fuel filters

Fuel filters filter the fuel to remove any dust and dirt before the fuel enters the system. So, when it happens, the regular flow of fuel is restricted, causing serious issues in the engine. You should replace the fuel filter once it is blocked, and it will only cost between $99.0-$119.99.

B. Fuel Injection system

The fuel injection system should be checked next for any pump leaks. Inspect the fuel injection pump for leaks and make any necessary repairs. Additionally, check for damaged or filthy injectors; if so, remove the fuel injectors and replace them with new ones.

It is better to take professional help to check the fuel injection system, and it can cost anywhere from $100-$300, depending on the degree of the damage.

5. Check the Coolant Level

Engine overheating is one of the key problems of Bobcat T190 and is mostly due to low maintenance. The most common issue that triggers this problem is a low coolant level along with a low level of engine oil.

Some uncommon issues like damaged radiator caps can also trigger this. Follow the steps below to solve this problem.

- Step 1: Check the coolant level

First, you will need to check the coolant level in the engine. When the coolant level on the engine is low, the engine starts to get overheated. So, if the coolant level is low, you will need to refill the coolant. Also, make sure to use good quality coolant for the engine.

- Step 2: Check the engine oil level

When the engine oil level is low, it can also cause engine overheating issues. So you should always check and fill the engine oil to the required level.

- Step 3: Check the radiator cap

If you see that both coolant and engine oil are up to the required level and of good quality, you should check the radiator cap. The radiator cap can get worn out in time and eventually get damaged. So, if they are damaged, you must replace them. A radiator cap can be found for between $10-$50.

6. Check and Change Gear Oil

Problematic final drive caused by gear oil is another significant difficulty the Bobcat T190 encounters. Gear oil will deteriorate and lose its efficacy over age. When subjected to high temperatures, that process of disintegration quickens. Regular checks and replacements of the gear oil are required.

So, to solve this issue, you will need to open up your final drive and check the gear oil whether it is too thick and the oil is contaminated or not. Thus, clean your final drive properly and make sure that the bearings are not damaged; if yes, you will need to replace them, which will cost around $20-$40.

Once the final drive is cleaned properly, and you have taken care of other internal components in it. Re Grease the gear with good quality gear oil and make sure to change at regular intervals.

Frequently Asked Questions (FAQs)

Down below, we will talk about a few of the faqs related to common problems of Bobcat t190. These questions and answers will help you to understand all these issues better.

How often should I change the final drive oil of my Bobcat T190?

Examining and replacing the final drive for the final drive to function well, gear oil is crucial. Approximately once each 100 hundred hours or once monthly, gear oil amounts must be examined. A final drive should have its gear oil changed roughly once per year.

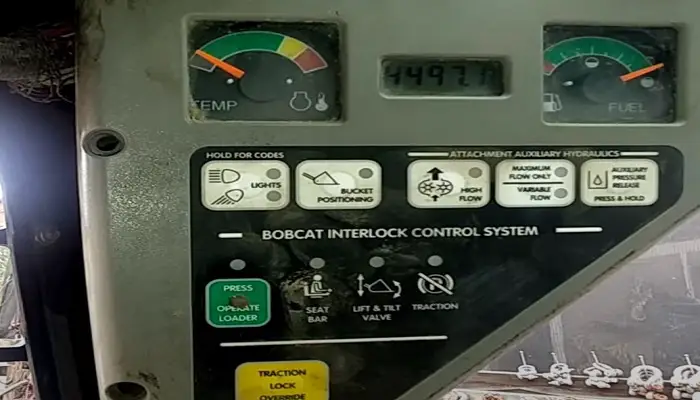

What Hydraulic fluid does a Bobcat T190 use?

The use of Bobcat’s all-season hydraulic fluid is advised. The oil is engineered to sustain consistency throughout durations of use at extreme temps yet while delivering optimal circulation at subfreezing temperatures. Bobcat claims that commercial fluids cannot replace their oil.

What is the average lifespan of a Bobcat T190?

A Bobcat T190 typically has a lifetime of 5,000 hours. Remember that a variety of factors, like the nature and complexity of the task you are employing the track loader for, affect how long your compact track loader will last.

How long do Rubber tracks last on a Bobcat T190?

Rubber tracks on a Bobcat T190 are quite durable and can last anywhere from 1200-16000 hours, depending on the usage and degree of pressure put into it during working. However, rubber tracks generally have a lifespan from 400-2000 hours.

Why do the tracks keep coming off in my Bobcat T190?

The de-tracking issue is frequently caused by damaged track springs and insufficient track spring pressure. This track adjustment components on the Bobcat T190 feature two options for track strain: loose for rubber tracks and firm for steel tracks.

Conclusion

The Bobcat T190 is a very popular choice all around the world but after using it for quite some time now we have found a few problems that users can suffer from. We have discussed all these probable problems and their solutions in this guide so far.

We believe by now you already know how to solve all these issues. Even though these issues might seem a bit complicated to solve but in reality, they are quite easy to fix. So, you need to be careful and find the exact source of the problems.

Always make sure to take safety precautions before working with your T190 to avoid any unwanted accidents.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!