5 Common Problems with Bobcat 751 and Their Solutions

From excavation, and demolition to the elimination of piles of debris, Bobcat 751 can handle various tasks ranging in size and difficulty. However, despite being a commonly used equipment, Bobcat 751 ran into issues. Some issues are common and can be solved by yourself, while others require professional help.

The most common Bobcat 751 problems include but are not limited to solenoid failure, losing belt, fuel pump failure, faulty steering, and the Bobcat 751 being difficult to start.

If you are struggling with one of these issues but do not know how to deal with it, keep reading. We will have a detailed discussion, including the easy-fixing strategy you don’t want to miss.

What Are The Common Bobcat 751 Problems?

The Bobcat 751 has an engine and other components that, like those in any other engine-operated vehicle, are subject to failure.

However, the key decision point for you should be whether you can troubleshoot and fix it on your own or if you should leave the job in the hands of a professional.

Here is guidance from us. You should leave the job to be handled by a professional if you lack the required knowledge, tools, or prior experience.

Anyway, if you have a Bobcat 751 for quite a long time, you should make yourself ready to face one of the following issues.

- Start Up Issue

- Fuel Pump Problem

- Faulty Steering

- Loose Belt

- Solenoid Failure

5 Solutions For Bobcat 751 Problems

We have stated that some problems with the Bobcat 751 are minor and have simple fixes, which can be resolved using a do-it-yourself strategy. On the other hand, some issues, such as the defective steering and solenoid issue, are considered major problems and demand that you call a professional.

Anyway, we’ve listed some of the most effective fixes for some Bobcat 751 issues here. Go ahead, give it a try.

1. Start-Up Issue: Check And Repair

Start-up issues may involve one or more engine components, ranging from the ignition coil to the Lucas pump. You may need to check a number of components before identifying the source of the issue. You might have to do the following checkup before finding the main culprit behind the start up issue.

- Check if the belt is loose and tighten properly.

- Inspect the ignition coil for signs of damage and replace it.

- Put sufficient fuel into the machine and inspect if the injector line has any leaks.

- The Lucas pump on the bobcat 751 engine might require replacing.

- Check if the battery performs enough revolutions for the machine to operate normally.

The process of identifying and fixing this problem takes a lot of time and patience. When it comes to fixing the start up issue, it actually depends on the severity and the cost of the replacement parts.

2. Fuel Pump Problem: Repairs And Replacements

This is yet another significant issue that you might experience. Fuel is like blood, and the pump is like the engine’s beating heart. A properly working pump distributes oil to the various engine components. On the other hand, Faulty pumps create an imbalance in the Bobcat 751.

You will experience a drastic drop in the efficiency of your machine, which includes not being able to take the regular load and sudden pauses. There can be many reasons behind the failure of the pump. Here is a to-do list to find the main reason behind the issue and fix it accordingly.

- Check the fuel filter for dirt or damage and clean or replace accordingly.

- Check if the primer balls are working right and pump them properly.

- Look thoroughly for air leaks and repair the fuel line if found any.

- Next, check if the lift pump is in working shape and replace it if it’s not working.

- Manually pump some fuel into the injector to check if it’s working. Thoroughly clean if dirty or replace it if damaged.

So these are the issues and some common fixes you can follow. When it comes to fixing the fuel pump, it costs more if you have to replace anything; if you are lucky, simply cleaning will solve the issue.

3. Faulty Steering: Add transmission Fluid, Replace parts or

Steering issues include the wheel sticks when it is turned left or right. You should check the hydraulic system. Also, the tank must have the required amount of fluid. Lack of fluid is another reason for the steering failure. When the symptoms of the steering issue come out, you can try one of the following:

- Check if there is any issue with the steering motor. You might have to replace the steering motor

- You might have to bleed the air from the system or replace the hydraulic pump and filter

- Try replacing all old hydraulic hoses to remove any clogged or damaged hoses.

- Make sure all the electrical connections are tightened

Hopefully, one of the reasons mentioned above is the culprit behind the Bobcat steering issue, and you will successfully come up with a solution in no time.

4. Loose Belt: Tighten The Belt

A common problem in almost all the construction equipment class machines is the loose belt. This loose belt will hamper efficiency while operating your machine.

The bobcat 751 loader will output low power and movement when affected by this problem. Follow the methods below to tighten the drive belt in no time.

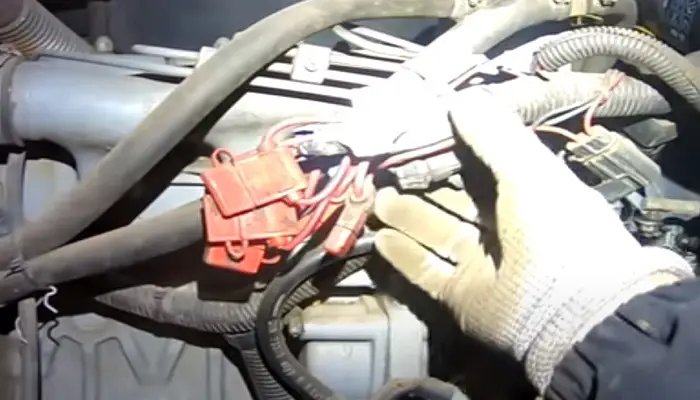

- Locate the drive belt and disconnect the battery connections with a socket wrench while wearing rubber gloves.

- Next, you have to lose the bolts that are responsible for attaching the bracket to the alternator.

- Take a non-conductive stick and pry it into the belt, remember to keep your pressure on the belt with the stick.

- Carefully take the alternator belt, put it in a new position, and tighten back the bolts.

- Once the alternator belt has been put in a new place and tightened, use tension testers to check.

- Reconnect the battery connections back to the belt and close the lid.

The problem can be fixed in a lot of ways but this is the simplest one by far. This problem doesn’t require any additional costs unless you hire. If you decide on fixing it yourself, remember to wear non-conductive gloves and goggles for safety.

5. Fuel Solenoid Failure: Check Linkage, and Voltage

The most common reasons for the failure of the Bobcat fuel solenoid include low voltage, improper linkage, and a damaged solenoid. Here are some of the common solutions that you can try.

- To solve the solenoid problem due to voltage issues, check several connection points using a multimeter and find out the damaged section and solve the issue.

- If the issue is the linkage, the solenoid cannot draw power. What you can do is run a wire from the solenoid to the battery; if the faulty solenoid works, then most probably, this is a linkage problem.

The cost of fixing depends on the severity. The mechanic will charge for the diagnosis and repair. You have to bear the replacement cost. On average, a bobcat 751 fuel solenoid costs $40 to $60.

Frequently Asked Questions (FAQs)

By now, you are pretty much clear about the common problems with the Bobcat 751 problems and fixing strategies. Here are some common frequently asked questions you might want to know.

Why is the Bobcat 751 not responding to steering controls?

The problem lies in the entire steering system of the loader and it’s gotten worse over the years. The final drive motor has constant issues and requires repairing or replacing. Costs will be from $600 to $2000 for replacing and repairing.

Why is my Bobcat 751 consuming too much fuel?

Problems like leak in the fuel lines are responsible for excess fuel usage. Fill your machine with an adequate amount of fuel and check below it to identify the leaks in the line. Clean and repair the fuel filter too.

How do I fix the computer attached to the Bobcat 751?

The computer gives the users commands to the machine and no access to the computer means you’ll have to fix it manually. Check the battery using a voltage checker and charge it manually.

Does the Bobcat 751 usually have a cold start?

Yes, the construction equipment has aged well and all of its parts have become quite rusty. Like a Windows 98 operating system, the bobcat 751 computer slowly starts up and the engine has a cold start.

Should I oil the arms of the Bobcat 751 to prevent problems?

No, the bobcat 751 has an automatic oiling mechanism that provides sufficient oil to all the mechanical parts. You can control the amount of oil intake using the attached computer and check how much oil you have left.

Conclusion

The Bobcat 751 skid-steer loader is one of the most common pieces of equipments that most people want to use. However, over time, it runs into issues and requires immediate attention before minor issues turn into major ones.

Don’t panic when problems arise; try to identify the exact cause and the best solution. The Bobcat 751 will stay by your side for a long time if the problems are fixed on time and properly maintained.

Hopefully, the blog was quite useful, and you were able to resolve the problem.

Say hello to Afrabby – your go-to research expert turned gardening expert, lawn care aficionado, and a skilled lawn mower mechanic! With years of hands-on experience and a passion for cultivating lush green landscapes, Afrabby is your partner in achieving the lawn of your dreams.

Whether you’re seeking expert advice on plant selection, weed control, or optimal mowing techniques, Afrabby’s got you covered. Equipped with the knowledge to diagnose and fix mower troubles, your lawn equipment is in safe hands. Let Afrabby transform your outdoor space into a stunning oasis you’ll love to show off!